Accuracy is critical in baby bottle sanitizers, where security and dependability directly influence a child’s well-being. For Original Equipment Manufacturers (OEMs), choosing the best parts, such as micro switches for these sanitizers, guarantees smooth performance and compliance with tough rules. This piece investigates why finely tuned micro switches are the leading pick for OEMs. It dives into their technical merits, design advantages, and manufacturing worth.

The Essential Role of Micro Switches in Baby Bottle Sanitizers

Micro switches are petite yet vital pieces in baby bottle sanitizers. They handle major tasks like starting power, timing the process, and ensuring safe stops. Thus, they keep the device running effectively and securely.

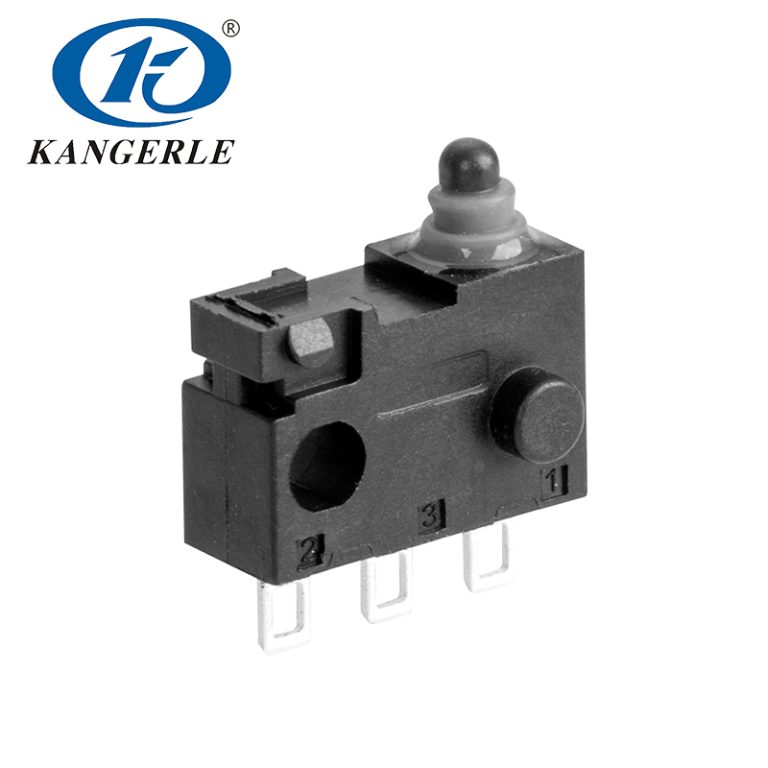

What Are Micro Switches?

Micro switches are small electrical-mechanical units that react to light force. In sanitizers, they notice lid closures, kick off heating phases, or pause the system if risks arise. Their trustworthiness makes them crucial for OEMs aiming to create superior, reliable items.

Why Accuracy Counts in Sanitizer Uses

In baby bottle sanitizers, even tiny mistakes can harm cleanliness or safety. Highly accurate micro switches bring clear benefits. They activate precisely at set pressure spots, delivering steady outcomes. Also, they switch rapidly, cutting delays in important stages. Plus, their lasting nature reduces wear over time. This prolongs the sanitizer’s life. These features support OEMs’ aims of providing dependable tools for parents.

Key Advantages of Accurate Micro Switches for OEMs

OEMs favor parts that improve item quality and streamline making them. Accurate micro switches succeed in both areas. Hence, they’re a top choice for baby bottle sanitizer layouts.

Heightened Safety Levels

Safety is absolute in baby items. Accurate micro switches help in key ways. They catch misaligned lids and stop the device. They also shut down power if it gets too hot. Moreover, they ensure cleaning cycles finish fully. This consistency aids OEMs in meeting standards like IEC 60335-1 for home tools, reducing legal worries.

Enhanced Power Savings

Power-smart layouts draw eco-friendly buyers and cut building costs. Accurate micro switches aid this effort. They limit energy loss by turning on only when required. They also back low-power idle modes. Additionally, they offer tight control over heating parts. For OEMs, this means competitive, earth-friendly sanitizer designs.

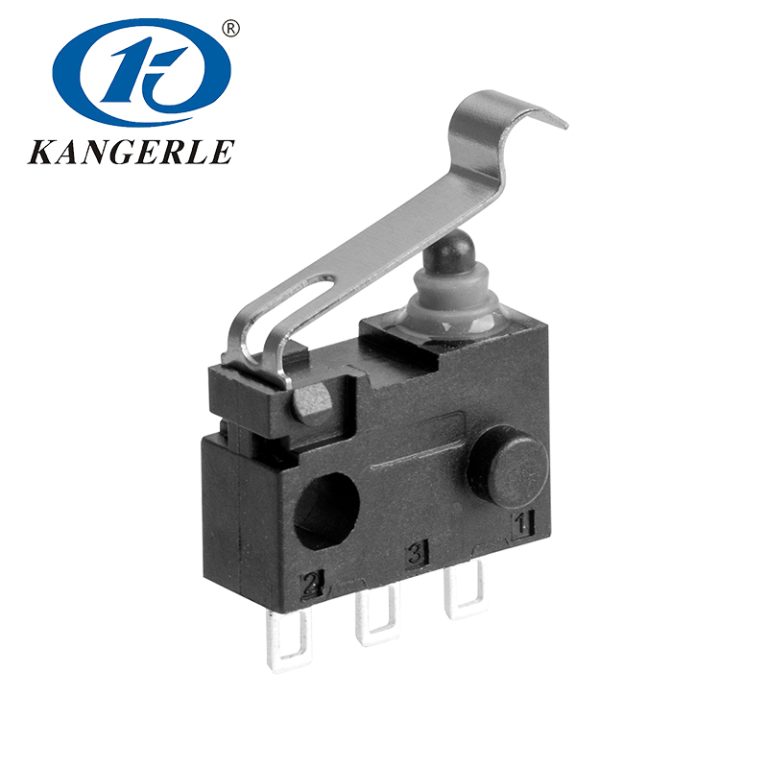

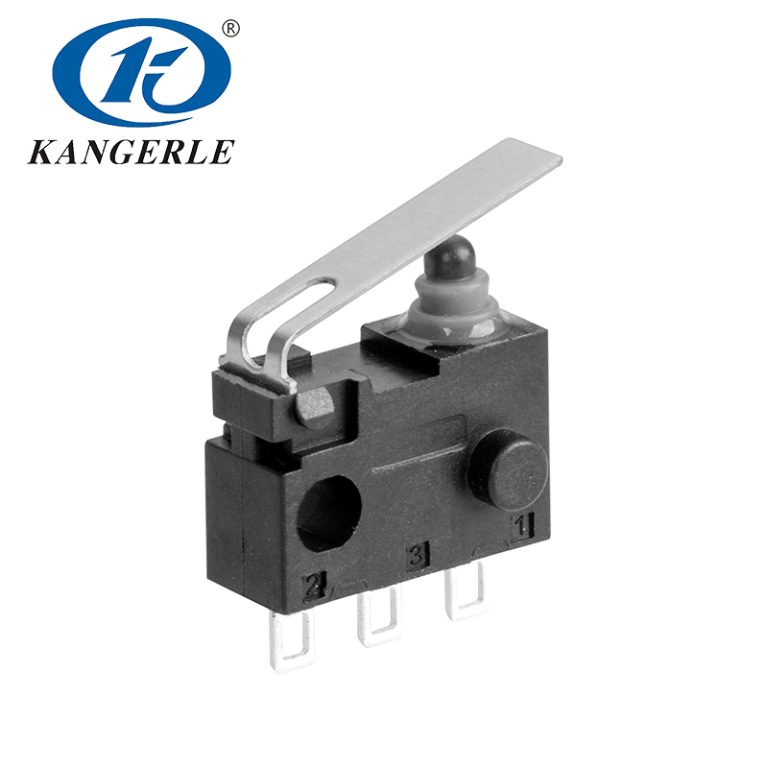

Strength and Lower Upkeep

OEMs want parts that handle constant use. Accurate micro switches, like certain lever types with circuit board ends, provide notable perks. They offer a long life, often hitting millions of uses. They resist dust and dampness, common in sanitizer settings. Plus, they stay steady despite heat shifts. This toughness reduces repair requests and boosts brand image.

Design Adaptability with Accurate Micro Switches

OEMs prize parts that suit varied sanitizer styles, from small countertop units to big-capacity ones. Accurate micro switches deliver this versatility.

Tiny Size for Space-Saving Layouts

Baby bottle sanitizers often aim for cramped kitchens. Some small micro switches stand out here. Their little size fits snug designs. They’re also light, easing the unit’s total weight. Plus, they blend easily with circuit board ends. This lets OEMs create freely without losing function.

Adjustable Choices for Specific Demands

Different sanitizer types need custom fixes. Accurate micro switches, like certain lever models, bring options. They feature changeable arm lengths for unique trigger spots. They offer various end types, like circuit or solder ones. Also, they provide different force levels to match design needs. This range helps OEMs meet broad market wants.

Technical Details OEMs Should Review

Selecting the right micro switch means checking specifics. Here’s a table summing up key traits for accurate micro switches in sanitizers:

| Feature | Specification | Benefit for OEMs |

| Operating Force | 0.5N–3N | Exact triggering, little effort |

| Electrical Rating | 5A at 125/250V AC | Meets sanitizer power needs |

| Life Expectancy | Up to 10 million cycles | Long-lasting trust |

| Temperature Range | -25°C to +85°C | Handles steam and warmth |

| IP Rating | IP40 or higher | Guards against dust and splashes |

These traits, found in models like those from certain small series, suit sanitizer demands.

Cost Savings and Making Benefits

Beyond work, accurate micro switches bring money-saving perks that attract OEMs during building and later.

Lower Building Costs

Accurate micro switches ease making tasks. Pre-checked parts cut fixes. Their standard shapes speed up lines. Also, they fit automated setups, reducing worker expenses. This efficiency keeps OEMs’ profits strong.

Fewer Returns and Repairs

Faulty switches cause pricey returns. Accurate models lower this risk. They keep quality steady across batches. They also pass tough strength tests. Plus, they back stable sanitizer use. Thus, OEMs spend less on after-sale help and gain buyer faith.

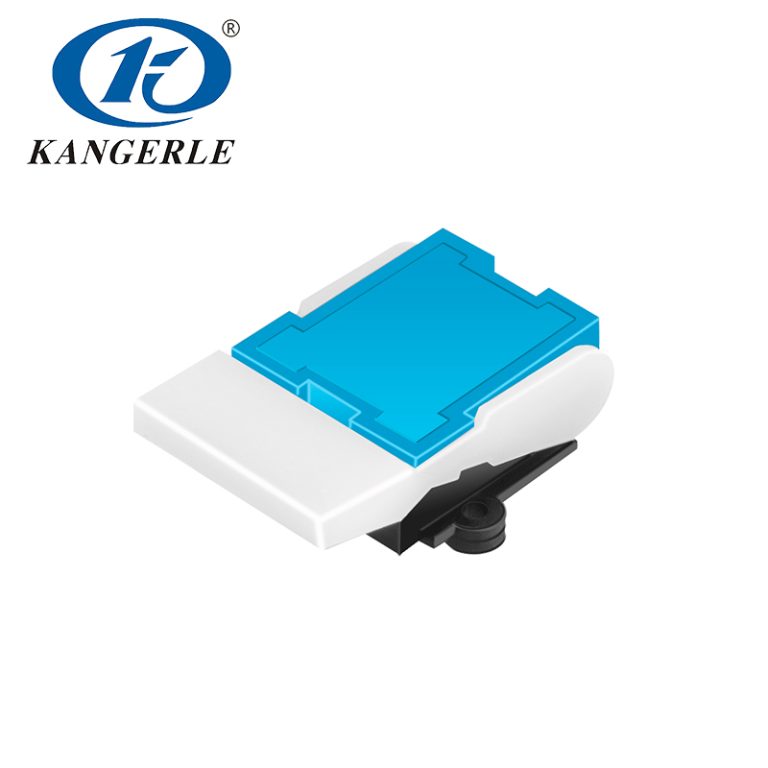

Real-Life Uses in Sanitizer Layouts

Accurate micro switches excel in practical cases. For example, they lock lids, halting the process if the top lifts mid-cycle. They also control timers, ensuring cleaning lasts the right time. Plus, they shield against overheating by cutting power when heat climbs too high. These uses show why OEMs add them to top sanitizer lines.

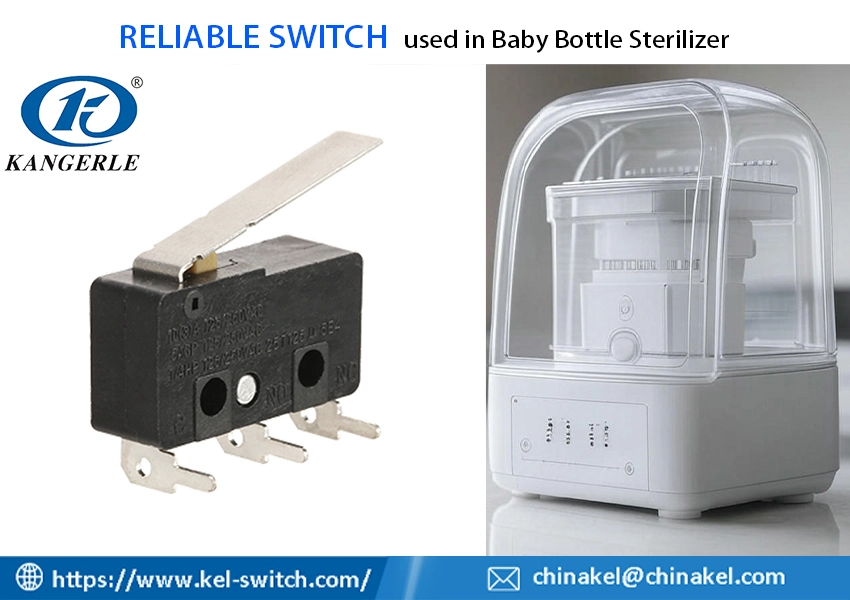

Why KANGERLE Shines as a Micro Switch Source

For OEMs seeking trustworthy parts, linking with a solid provider matters. KANGERLE leads in offering micro switches. With over 20 years of know-how, KANGERLE focuses on top-quality, finely crafted switches for tools like baby bottle sanitizers. Their drive for new ideas, strict testing, and global approvals (e.g., UL, CE) make them a dependable pick for OEMs worldwide.

FAQs: Accurate Micro Switches in Baby Bottle Sanitizers

What makes accurate micro switches unlike standard ones?

Accurate micro switches have stricter limits, swifter responses, and greater strength. This ensures steady work in key uses like sanitizers.

How do micro switches boost sanitizer safety?

They spot risky states, like open lids or excess heat, and stop power. This guards users and meets official rules.

What durability can OEMs expect from a micro switch in a sanitizer?

Based on the type, they can last up to 10 million uses. This fits years of regular use in normal settings.

Conclusion

Accurate micro switches are a bedrock of today’s baby bottle sanitizer layouts. They give OEMs safety, savings, and adaptability. By picking top-tier options from trusted sources like KANGERLE, makers can deliver dependable, market-topping items.