Tactile switches, also known as tactile pushbuttons, are widely used in various electronic devices due to their simplicity, reliability, and the unique tactile feedback they provide.

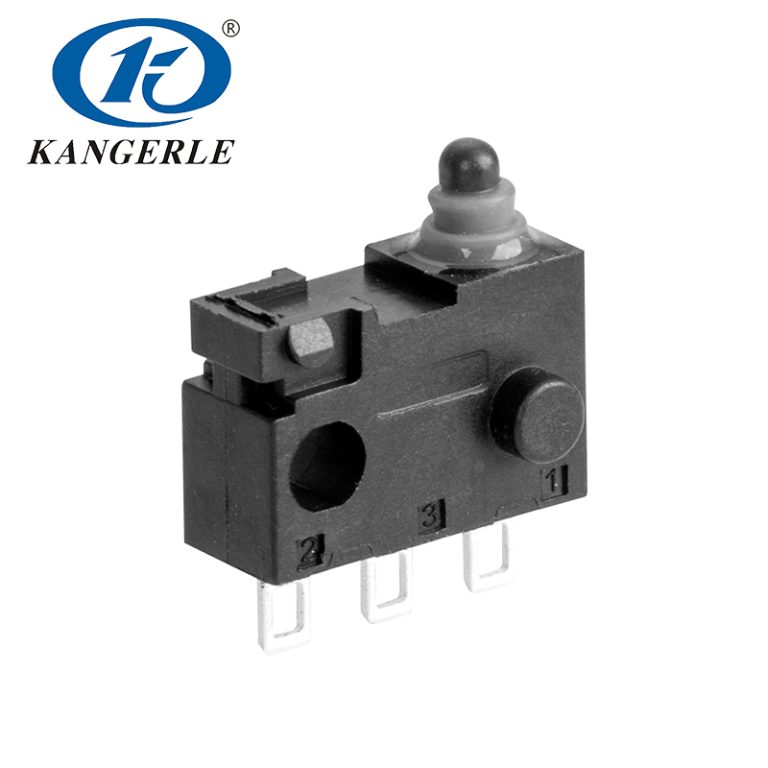

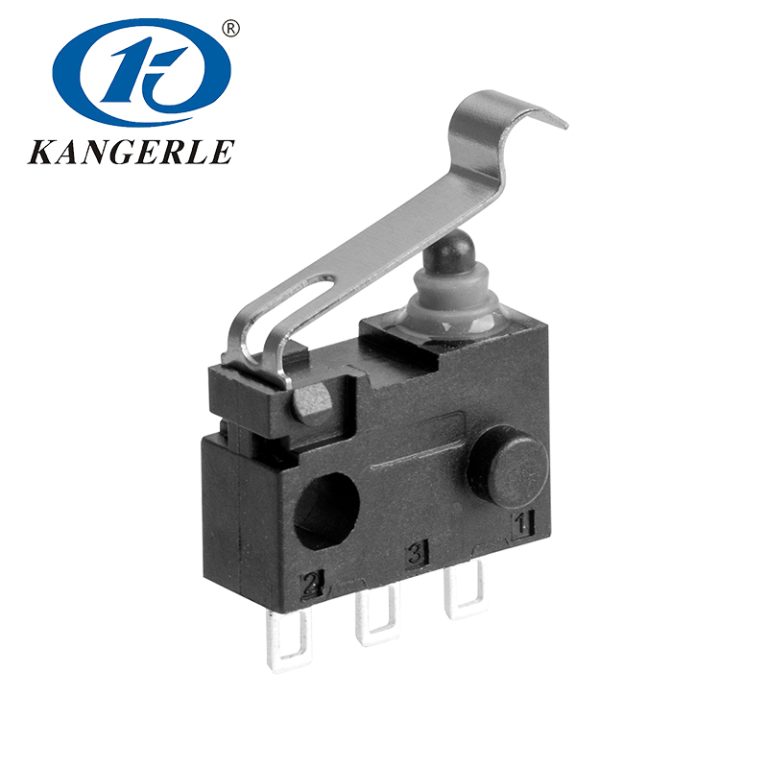

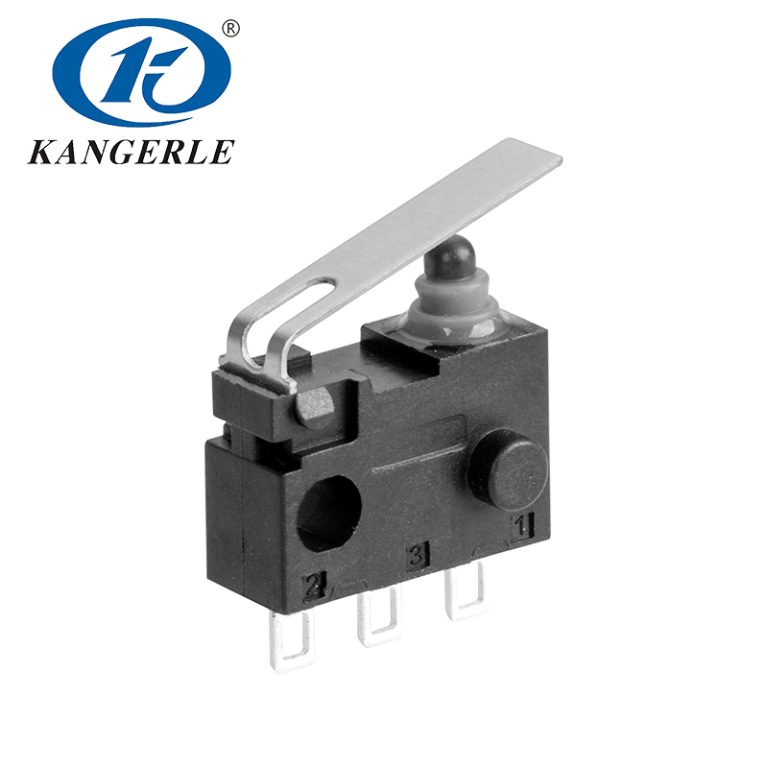

As you can see, a tactile switch mainly consist of a plunger, cover, movable contact, base, and terminals. These switches are small, momentary push buttons that, when pressed, give a noticeable tactile feedback or “click” to the user. This click response is highly valued in applications where precise and deliberate input is required. In this article, we will explore the features, types, and applications of tactile switches, highlighting their importance in modern electronics.

Features of Tactile Switches

1. Click Response

Tactile Feedback: One of the most distinguishing features of tactile switches is their click response. This feedback mechanism gives users a tactile sensation, often accompanied by an audible “click,” indicating that the switch has been successfully actuated. The tactile feedback is produced by a contact dome inside the switch, which collapses when pressed and returns to its original shape when released. This ensures that users receive immediate and clear confirmation of their input, which is particularly valuable in applications where visual confirmation is impractical.

User Experience: The click response enhances the user experience by providing a sense of precision and control. This is crucial in devices like remote controls, game controllers, and keyboards, where users rely on tactile feedback to know that their input has been registered accurately. The clear, positive response reduces the likelihood of input errors and increases user satisfaction.

2. High Durability

Longevity: Tactile switches are designed to withstand many operations, making them highly durable. The internal mechanism, often a contact dome, is engineered to endure millions of presses without significant degradation in performance. High-quality tactile switches can typically last for 100 thousand to 10 million cycles, depending on the design and materials used. This longevity ensures that the switches remain functional over the lifespan of the device, reducing the need for frequent replacements.

Materials and Construction: The durability of tactile switches is largely due to the materials and construction techniques used in their manufacture. The switches are often made with robust materials like stainless steel for the domes and high-quality plastics for the housing. Additionally, the contacts are designed to resist wear and corrosion, ensuring reliable performance even in harsh environments.

3. Compact Size

Space Efficiency: Tactile switches are typically small and compact, making them ideal for applications where space is limited. Their compact size allows them to be easily integrated into densely populated printed circuit boards (PCBs) without taking up excessive space. This is particularly important in portable and handheld devices where internal space is at a premium.

Versatility: The small size of tactile switches does not compromise their versatility. They come in various sizes and shapes, with different actuation forces and travel distances, allowing designers to choose the most suitable switch for their specific application. Whether it’s a slim, low-profile switch for a sleek handheld device or a more robust switch for industrial equipment, there is a tactile switch to meet the requirements.

4. Easy Integration

Mounting Options: Tactile switches are designed for easy integration into electronic circuits. They are available in both through-hole and surface-mount configurations, making them compatible with various PCB assembly processes. The through-hole switches are ideal for applications requiring strong mechanical bonds, while surface-mount switches are suitable for automated, high-speed PCB assembly.

Design Flexibility: The variety of mounting options and configurations provides designers with flexibility in incorporating tactile switches into their products. This ease of integration simplifies the design and manufacturing process, reducing development time and costs.

5. Customizability

Actuation Force and Travel: Tactile switches can be customized to meet specific requirements for actuation force and travel distance. Actuation force refers to the amount of pressure needed to actuate the switch, which can vary from light to heavy. Travel distance is the distance the switch moves when pressed. Customizing these parameters allows designers to tailor the tactile response to the needs of their application, ensuring optimal user experience and performance.

Aesthetic Options: In addition to functional customizations, tactile switches can also be tailored aesthetically. They are available in various colors, shapes, and sizes to match the design and branding of the end product. This aesthetic flexibility makes tactile switches suitable for consumer electronics, where the look and feel of the interface are important.

Types of Tactile Switches

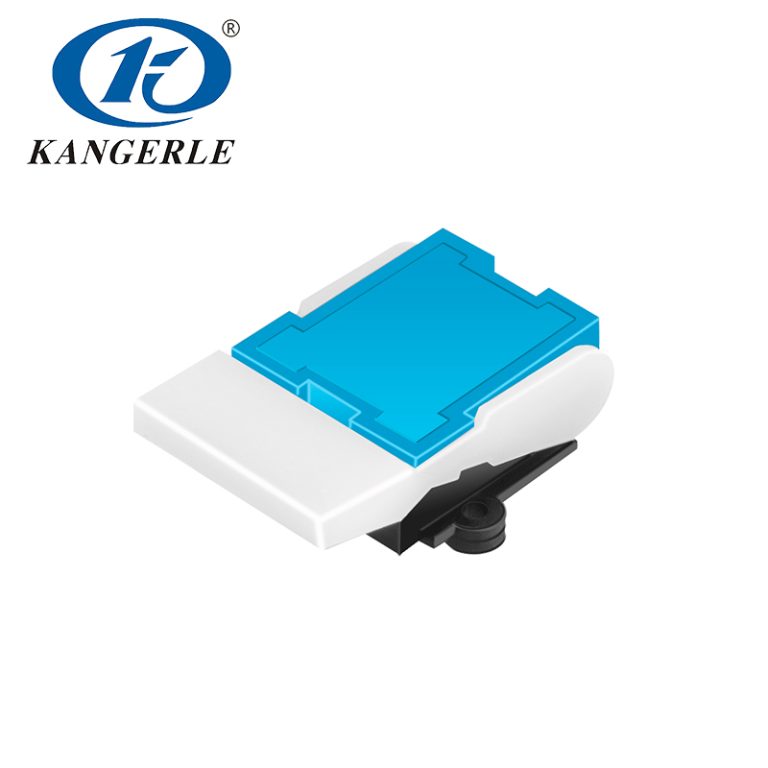

Broadly speaking, tactile switches can be divided into two categories: standard types and waterproof types. Waterproof tactile switches are also dust-proof, making them suitable for use in harsh environments. They can be further divided into two types: PCB through-hole types and PCB surface-mount types. For PCB through-hole types, the terminals are inserted into the holes on the PCB and secured by soldering. For PCB surface-mount types, the terminals are directly surface-mounted and soldered onto the PCB. These switches can be individually packaged and transported, or transported using tape packaging methods, where the tape secures the switches and maintains spacing.

Other specifications include vertical, side-press, long-travel, bracket-mounted, horizontal, and ultra-miniature tactile switches, among others. They come in various shapes and specifications to meet a wide range of application needs.

Applications of Tactile Switches

Tactile switches are versatile components used in a wide range of applications across various industries. Here are some common applications:

1. Consumer Electronics

Tactile switches are prevalent in consumer electronics due to their compact size and reliable performance. They are commonly found in remote controls, game controllers, and handheld devices. The click response of tactile switches provides users with immediate feedback, enhancing the user experience in devices that require frequent interaction.

2. Computer Peripherals

Keyboards are a primary example of tactile switch applications in computer peripherals. Mechanical keyboards, in particular, use tactile switches to provide a satisfying typing experience with a distinct tactile and auditory response. This feedback helps typists ensure that each keystroke is registered, improving typing speed and accuracy.

3. Industrial Equipment

In industrial settings, tactile switches are used in control panels, instrumentation, and machinery. The durability and reliability of tactile switches make them ideal for environments where equipment is subject to heavy use and harsh conditions. The tactile feedback ensures operators can confidently operate machinery and equipment, reducing the likelihood of errors and enhancing safety.

4. Medical Devices

Medical devices, such as diagnostic equipment and patient monitoring systems, often incorporate tactile switches. The waterproof tactile switches are particularly valuable in these applications due to the need for hygiene and the potential exposure to liquids. The tactile feedback ensures that medical professionals can operate the devices accurately, even in stressful situations.

5. Automotive Industry

In the automotive industry, tactile switches are used in various control systems, including dashboards, steering wheel controls, and infotainment systems. The tactile response provides drivers with a reliable and intuitive way to interact with their vehicle’s controls, enhancing the overall driving experience. Waterproof tactile switches are also used in exterior applications, such as door handles and trunk release buttons, where exposure to the elements is a concern.

6. Home Appliances

Tactile switches are widely used in home appliances such as microwaves, ovens, washing machines, and refrigerators. These switches provide a reliable and user-friendly interface for controlling the appliance’s functions. The tactile feedback ensures that users can operate the appliances confidently, knowing that their inputs have been registered accurately.

7. Wearable Devices

Wearable devices, including fitness trackers and smartwatches, often incorporate tactile switches for user input. The compact size and reliability of these switches make them suitable for small, portable devices. The tactile feedback enhances the user experience by providing a clear indication of input, even on small screens or in situations where visual confirmation is not possible.

Conclusion

Tactile switches are an integral component in modern electronic devices, offering reliable performance, high durability, and a satisfying tactile feedback. Their versatility and robustness make them suitable for a wide range of applications, from consumer electronics and computer peripherals to industrial equipment and medical devices. The development of waterproof tactile switches has further expanded their use in environments exposed to moisture and contaminants. As technology continues to advance, tactile switches will remain a fundamental element in ensuring reliable and user-friendly interfaces across various industries.

Tactile Switches Manufacturer from China

Zhejiang Kangerle Electronics Co., Ltd., was established in 1993 and is located in Yueqing City, Zhejiang Province. With 30 years of experience in the switch industry, Kangerle specializes in the production and sales of tactile switches, micro switches, push button switches, rocker switches, and slide switches. Our products undergo stringent quality control, comply with ISO9001 and IATF16949 quality management system certifications, and have obtained various international certifications such as UL, TUV, CE, CB, CQC, and RoHS.

Kangerle tactile switches are manufactured using high-quality materials and advanced technology, ensuring product reliability and durability. The company operates multiple automated production lines, producing tactile switches including standard tactile switches, waterproof tactile switches, and illuminated tactile switches. These come in various structural forms, such as SMD type, DIP type, top-push type, and side-push type. There is also a wide range of specifications including ultra-miniature, 3×4mm, 3×5mm, 3×6mm, 4.5×4.5mm, 6×6mm, and 12×12mm series. Our tactile switches are widely used in household appliances, automotive parts, medical devices, communication equipment, electronic products, and smart home applications.

Kangerle emphasizes technological innovation and research and development capabilities, boasting a professional R&D team that continuously improves and innovates products to meet market demands. Additionally, the company offers flexible OEM/ODM customization capabilities, providing tailored solutions according to customer requirements, including switch design and mold customization. For more information, please visit our company website: https://www.kel-switch.com/.