Micro switches are switches that respond to minimal physical pressure and are popular in household appliances and power tools for their precise and dependable performance capabilities across various sizes and setups available to cater to diverse requirements. Kangerle provides an extensive range of micro switches, for purchase through their online platform.

How Does a Micro Switch Work?

The operation of a micro switch involves the utilization of a lever or button that’s spring-loaded to either open or close electrical contacts swiftly and effectively when pressed down. This quick “snap action” facilitates the switch’s transition between the closed states reliably and consistently with minimal effort, on the user’s part.

What Makes KW12 Subminiature Micro Switches Suitable for Water Heaters?

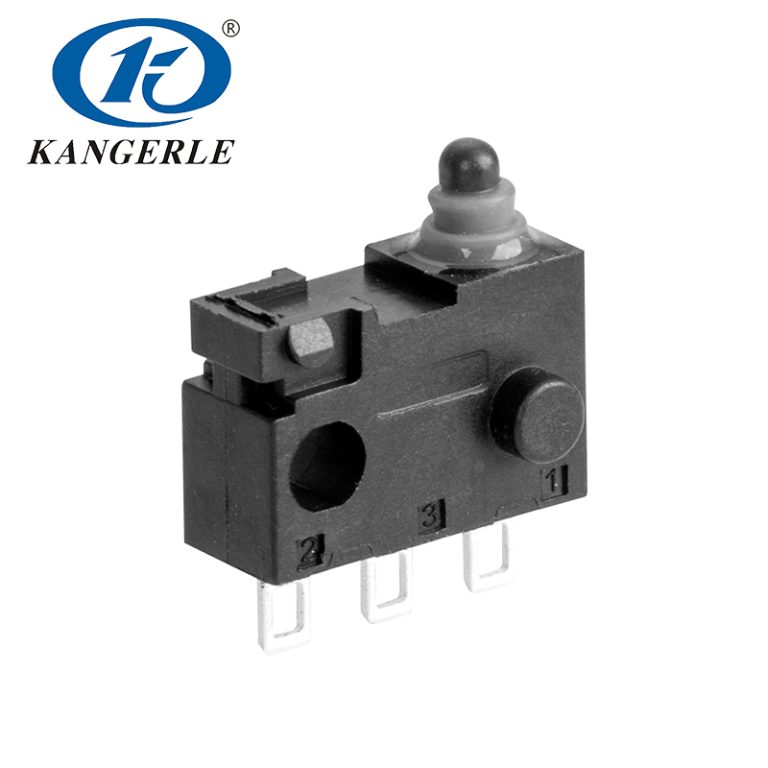

The KW12 subminiature micro switch is commonly selected for incorporation in water heaters due to its size and versatility in various setups, and its heightened sensitivity to triggers, in this context specifically.

- Compact Size: Water heaters come with room for internal parts; therefore having a small micro switch like the KW12 subminiature one is crucial for easy fitting, in tight spaces.

- High Sensitivity: The KW12 subminiature microswitch is extremely sensitive. Can be triggered by even a slight force input. Its sensitivity plays a role in water heaters as it enables the switch to respond to fluctuations, in temperature or pressure.

- Global Safety Certifications: The KW12 subminiature micro switch has received global safety certifications, including CB, CE, CQC, TUV, UL, and RoHS. This ensures that the switch meets the highest safety standards and can be used in appliances like water heaters.

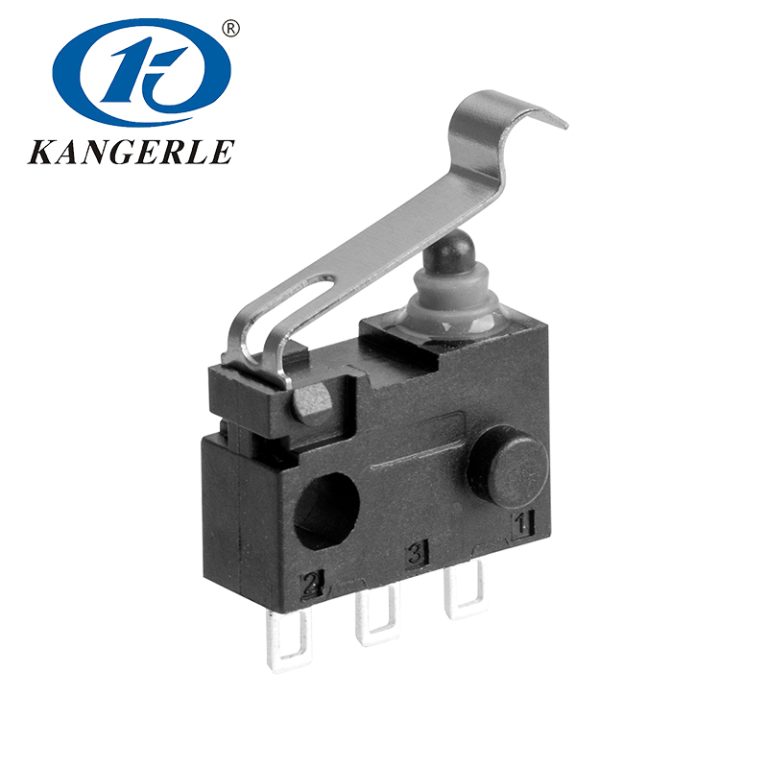

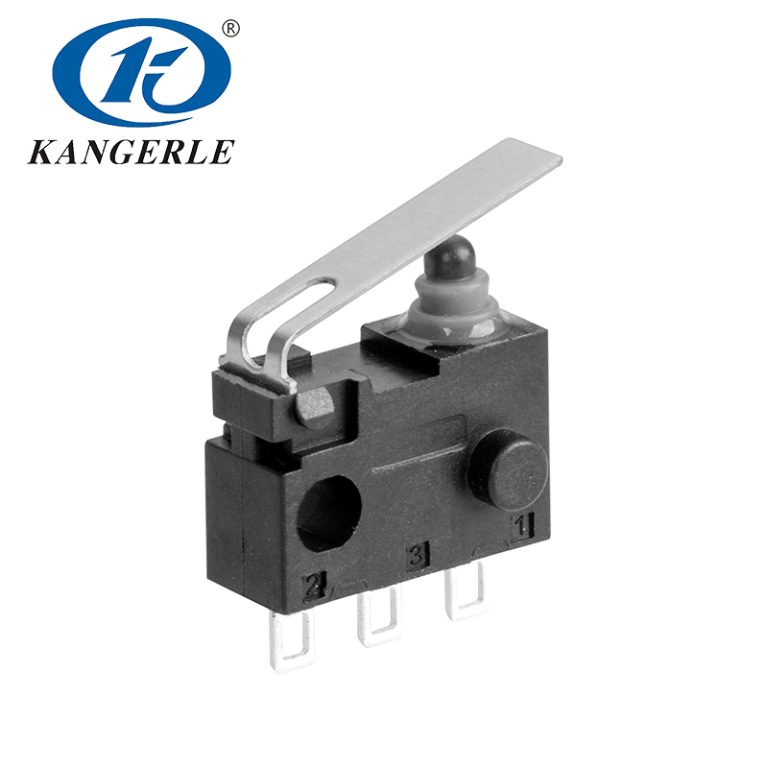

- Variety of Movable Arms, Operating Forces, and Wiring Terminals: The KW12 subminiature micro switch comes in options for movable arms and operating forces as well as wiring terminals to cater to your specific needs, for a water heater setup.

- Different Load Ranges: The KW12 subminiature micro switch comes in load capacities to accommodate a range of electrical currents—an essential feature, for water heaters that vary in size and power requirements.

What are the Specific Applications of KW12 Subminiature Micro Switches in Water Heaters?

KW12 subminiature micro switches find application in a range of uses within water heaters.

- Temperature Control: The KW12 subminiature micro switch could serve as a thermostat, for regulating the water temperature in a water heater; It gets triggered once the water temperature hits a level to shut off the heating element; and when the water temperature falls below that level again it deactivates to switch the heating element back on.

- Safety Mechanisms: The KW12 subminiature micro switch is suitable for use, in safety mechanisms to prevent the water heater from overheating or working in conditions. For instance, The switch can cut off power to the heating element should the water temperature rise high.

- Flow Control: The KW12 subminiature micro switch is handy, for sensing water flow in a water heater system. It gets triggered as soon as water begins to flow through the unit which then activates the heating component. When the water flow ceases the switch is deactivated resulting in the shutdown of the heating element.

ODM: Can Kangerle Customize KW12 Subminiature Micro Switches for My Specific Water Heater Needs?

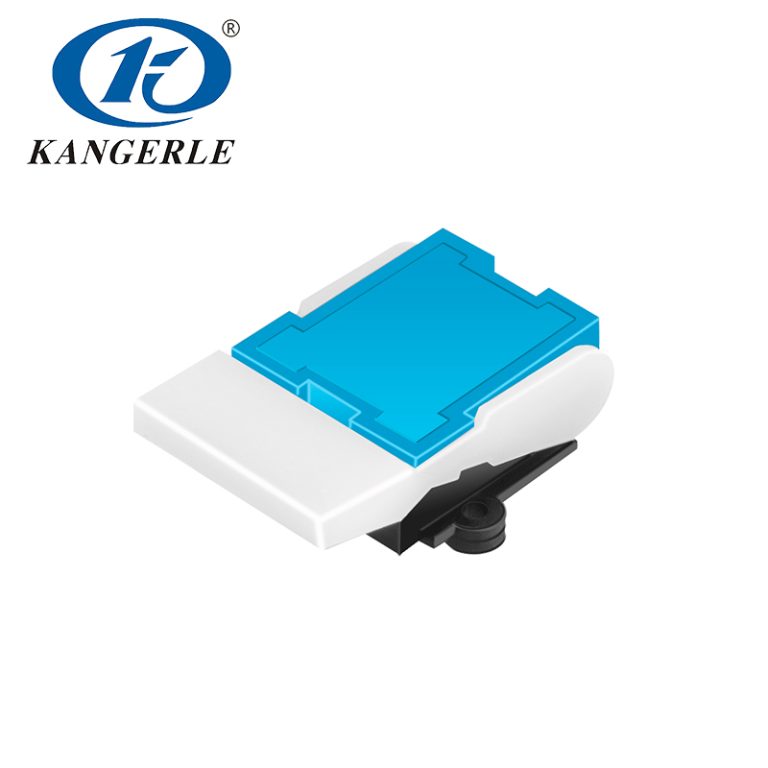

Sure! Kangerle can customize KW12 subminiature micro switches to suit your requirements for a water heater application. If you require a personalized micro switch for your water heater setup, Kangerle can collaborate with you to create and produce a switch that aligns with your needs. Kangerle provides OEM and ODM services for micro switches. To explore further about Kangerle’s OEM services, you can check out their website.

- What is Kangerle’s Customization Process?

Here is a breakdown of the customization process, at Kangerle:

- Mold Design: First, Kangerle will work with you to determine the specific requirements for your micro switch. This includes things like the size and shape of the switch, the operating force, the electrical rating, and any other special features that you may need. Once the requirements are finalized, Kangerle will create a mold design for your custom switch.

- Make Molds: After you approve the mold design, Kangerle will use professional equipment to create the molds for your custom switch.

- Free Samples Tests: Once the molds are complete, Kangerle will manufacture a small batch of samples of your custom switch and send them to you for testing.

- Mass Production: If you are satisfied with the samples, Kangerle will proceed with the mass production of your custom micro switches.

At Kangerle’s factory, they have top-of-the-line manufacturing tools and a skilled team of engineers and technicians dedicated to crafting your personalized micro switches with quality standards in mind.