Overview

Metal push button switches are electronic switches featuring a durable metal shell and an operational button. Unlike their plastic counterparts, these switches can withstand significant external pressure and environmental challenges. Their design ensures a high level of reliability, making them suitable for various applications ranging from home appliances to complex industrial equipment. As industries strive for more efficient and durable control systems, the adoption of metal push button switches has surged, showcasing their importance in modern control units.

Importance in Electrical Current Control

Metal push button switches are integral to controlling electrical currents effectively within a system. They serve two main functions: conducting and interrupting electrical flow. When activated, these switches establish a secure connection that allows current to flow seamlessly to the desired circuit. Conversely, when the button is released or pressed again, the connection is interrupted, stopping the electrical flow. This ability to control the electrical current is fundamental in numerous applications, ensuring that machinery and devices operate safely and efficiently.

Conducting and Interrupting Electrical Flow

The operational mechanism of metal push button switches is straightforward yet vital for industrial and commercial applications. By utilizing a reliable conductive material, they provide a consistent flow of electricity through established circuits. The momentary or latching functions of these switches allow them to be used in varying applications, depending on how long the connection should last. This adaptability is essential in environments that require precise electrical control to prevent malfunctions and damage.

Applications in Modern Control Units

Metal push button switches find extensive use in modern control units across different industries. Their robustness and versatility enable them to serve in applications from industrial automation systems to vehicles.

Industrial Automation

Automation Equipment Control Panel

In automation equipment control panels, metal push button switches serve as the primary interface for operators. These switches facilitate immediate responses to commands and adjustments, critical in high-paced industrial settings. Their tactile feedback assures that commands have been executed, aiding in error reduction and enhancing workflow efficiency.

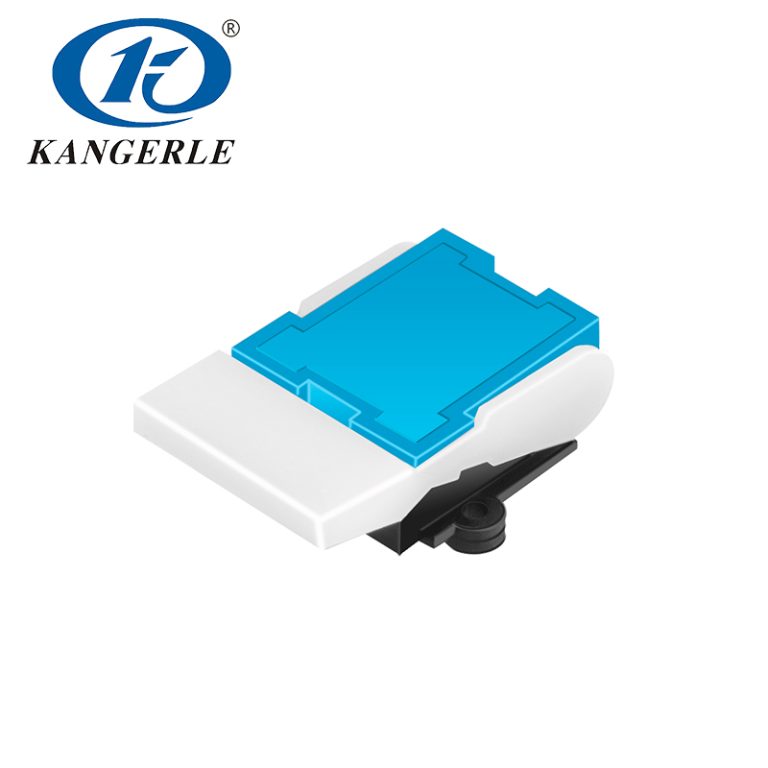

10a 220v Ring Power Led High Head Metal Push Button Switch from Kangerle

The Kangerle 19E Series Metal Push Button Switch is a robust and reliable electronic component designed to withstand harsh environments and heavy-duty applications. This switch features a metal shell and button, ensuring durability and the ability to withstand greater external forces compared to plastic button switches. Its sleek and sophisticated design not only looks great but also provides exceptional touch and operability.

Equipped with a 10A 220V rating, this high-head metal push button switch incorporates an LED indicator for added convenience and visibility. Its waterproof, dustproof, and corrosion-resistant properties make it suitable for use in a wide range of applications, including home appliances, industrial control equipment, power equipment, communication devices, medical devices, military equipment, and automotive electronics.

Transportation

Transportation also heavily relies on metal push button switches, particularly in the creation of control panels for vehicles like RVs and yachts. These switches must meet stringent durability standards while providing an intuitive interface for users.

RV Control Panel

In RV control panels, metal push button switches contribute to the seamless operation of multiple systems, including lighting, heating, and auxiliary power. Their presence enhances user interactions by simplifying the control of essential functions, making travel more comfortable and convenient.

Yacht Control Panel

Similarly, yacht control panels utilize metal push button switches to manage crucial systems efficiently. The exposure to marine environments necessitates switches that resist corrosion and perform reliably under varying conditions. The durability of metal push button switches ensures that yacht operators can depend on them for essential operations while navigating watercraft.

Metal Emergency Stop Push Button Switch

Experience is enhanced safety and reliability with Kangerle’s Metal Emergency Stop Push Button Switch, part of the comprehensive Emergency Stop Push Button Switch series. This high-quality switch is designed to meet the demands of critical safety applications, ensuring a swift and reliable emergency shutdown when needed.

With a rated load of 5A 110V AC, this switch is capable of handling various electrical loads while maintaining optimal performance. Operating within a temperature range of -20°C to 55°C, it can withstand extreme environmental conditions, ensuring uninterrupted operation. The operating force of 1NO 4.7N/2NO 6.6N ensures a responsive and secure activation, while the function options of 1NO1NC/2NO2NC provide flexibility to suit your specific application requirements.

Durability is a key feature of this switch, with an electrical life of up to 50,000 cycles and a mechanical life of up to 2,000,000 cycles. This ensures long-term reliability and minimal downtime, reducing maintenance costs and increasing overall productivity. Besides, complying with RoHS, CE, and CCC certifications, this switch adheres to strict international standards for safety, quality, and environmental protection.

Key Features and Benefits of Metal Push Button Switches

Metal push button switches bring various features and benefits that make them indispensable in control units.

Durability and Longevity

One of the most notable features of metal push button switches is their durability and longevity. Constructed from robust materials, they can withstand significant force, making them less prone to failure compared to plastic alternatives. Their resistance to environmental factors such as moisture, dust, and corrosion further extends their lifespan.

Material Strength and Resistance

The material strength of these switches directly impacts their performance in various applications. Metal push button switches are engineered to endure harsh conditions, ensuring that they maintain functionality over time. This resilience is particularly important for equipment that operates in demanding settings, ensuring ongoing reliability and reduced maintenance costs.

User-Friendly Interface

Design considerations for metal push button switches focus heavily on the user experience. They typically feature a user-friendly interface characterized by tactile feedback and ergonomic design. This promotes easier engagement with the switches, reducing the likelihood of user error and improving overall operational safety.

Tactile Feedback and Ergonomics

The tactile feedback offered by metal push button switches is crucial for operator confidence. Users can feel a positive response when the switch is engaged, providing reassurance that their input has been recognized. Ergonomically designed buttons also contribute to comfortable usage, which is particularly important in environments where operators frequently interact with control interfaces.

Customization Options

Customization is another key advantage of metal push button switches. Manufacturers often provide a range of sizes, colors, and configurations to suit specific applications. This flexibility allows engineers and designers to integrate switches that align with the visual and operational aesthetics of control units effectively.

Range of Sizes, Colors, and Configurations

The availability of various sizes and configurations means that engineers can find specific models that meet the unique requirements of their projects. Whether for industrial settings or consumer applications, customization ensures that metal push button switches can be tailored to fit in seamlessly with existing designs.

In conclusion, metal push button switches are integral to the functionality and reliability of modern control units. Their robust construction, versatility, and user-friendly design make them essential components in various industries, from industrial automation to transportation. As technology continues to evolve, the demand for these reliable switches is only expected to increase, solidifying their role in future applications.

Kangerle – Your Trusted Source for High-Performance Switches

Kangerle stands out in the realm of electrical components, particularly in the production of reliable metal push button switches. Known for our high-performance design and manufacturing, we are committed to supplying switches that adhere to rigorous quality standards. Our dedication to innovation has allowed us to create an expansive series of metal push button switches suited for diverse applications. Clients across various sectors look to us for dependable solutions that enhance the functionality of their equipment.

Metal Push Button Switch Series

Our extensive metal push button switch series includes various models, sizes, and features designed to cater to different industrial and commercial needs. Each series showcases durability, aesthetic appeal, and technical precision that meets contemporary demands. With options like waterproof and corrosion-resistant switches, our products are tailored for environments where reliability is non-negotiable. The diverse designs, from compact switches to larger units with extensive features, promote flexibility in implementation, allowing engineers to select suitable options for their specific applications.

ODM/OEM Service

Kangerle provides comprehensive Original Design Manufacturer (ODM) and Original Equipment Manufacturer (OEM) services. This allows clients to customize their metal push button switches according to individual specifications and requirements. Our capability in bespoke design options does not compromise the robustness and efficiency of our switches, as each product undergoes strict testing to ensure durability in its intended environment. By partnering with Kangerle, companies benefit from tailored solutions that align with their operational standards while maintaining competitive quality and performance.

Technological Advancements in Push Button Switch Design

Modern design continues to evolve, influenced by advancements in material science and technology that have transformed the manufacturing of push button switches. These developments focus on ensuring both functionality and safety, which are critical aspects for operators and engineers alike. Enhanced design protocols lead to switches that meet industrial demands while being user-centric in their application.

Innovations in Material Science

The application of cutting-edge materials in the manufacturing of metal push button switches significantly enhances their performance and lifespan. Innovations such as the use of advanced alloys and surface treatments improve resistance to environmental challenges such as moisture and corrosion. This progress ensures that the switches function efficiently even in harsh conditions. In addition, the integration of LED lighting technology within the metal buttons not only increases visibility in low-light settings but also adds an aesthetic dimension to the design, making them suitable for modern control panels.

Enhanced Safety Features

Safety remains a paramount concern in the design of metal push button switches. The introduction of enhanced safety features, such as improved actuation mechanisms and emergency stop functionalities, promotes safer operation within various applications. Moreover, switch configurations are designed to prevent accidental activation, ensuring that operators can effectively manage the equipment without undue risk. By prioritizing safety in our designs, we ensure that metal push button switches contribute to a safer working environment while maintaining high operational effectiveness.

Future Prospects

The future of metal push button switches is promising as industries increasingly recognize their significance in developing advanced control ecosystems. Ongoing technological developments and growing automation trends will continue to shape the way these switches are utilized across various sectors. Companies are expected to further integrate these components into their systems, enhancing overall efficiency and control capabilities.

As companies continue to prioritize reliability, safety, and ease of use, the demand for high-quality metal push button switches will remain robust. The ability to produce customized switches while adhering to strict quality standards positions Kangerle as a leader in meeting industry needs. Our commitment to innovation, combined with our comprehensive service options, will ensure that we remain at the forefront of metal push button switch technology.

In conclusion, the role of metal push button switches is integral to the future of automation, emphasizing their value in modern control units. The development of advanced features and safety enhancements reflects ongoing trends in engineering and user experience, guiding the evolution of electrical control mechanisms. As technology progresses, so too will the functionalities of these essential components, reinforcing their importance across various applications and industries.