The Function of Rocker Switches in Industrial Environments

The Basics of Rocker Switches

Mechanism and Design

Rocker switches are fundamental components in a wide array of electronic devices. These switches operate by rocking back and forth and are designed to establish or interrupt electrical connections. Their simplistic, yet effective, mechanism involves a spring-loaded rocker arm that is pivoted in the center. When one side of the rocker is pressed, it either completes or breaks the circuit, thereby controlling the flow of electricity. This makes rocker switches highly intuitive and user-friendly, facilitating easy operation even in complex industrial environments.

Common Types of Rocker Switches

There are various types of rocker switches, each tailored to specific needs and applications. Standard rocker switches are the most commonly used and are apt for general purposes. Waterproof rocker switches are designed for environments where moisture and water exposure are prevalent, ensuring reliability and safety. Illuminated rocker switches come with built-in lights, making them ideal for use in low-light or high-visibility requirements. These variations exemplify the adaptability and versatile application of rocker switches across different settings.

Applications in Various Industrial Sectors

Manufacturing

In the manufacturing sector, rocker switches play a pivotal role in machinery and equipment. They are often employed in control panels, conveyor systems, and production lines, providing operators with straightforward, on-the-spot control over various processes. The ease of use and reliability of these switches ensure minimal downtime and maximum productivity, which are critical in high-demand manufacturing scenarios.

Transport and Automotive

The transport and automotive sectors greatly benefit from the implementation of rocker switches. These switches are commonly integrated into vehicle dashboards, managing features such as lighting, air conditioning, and various other electronic functions. Their durable design ensures they can endure the demanding conditions typical of automotive settings, including vibrations, temperature variations, and constant use, thereby improving operational efficiency and safety.

Construction and Heavy Machinery

In construction and heavy machinery, the durability and simplicity of rocker switches are particularly advantageous. These switches are used to control various aspects of machinery operation, such as starting and stopping engines, actuating hydraulic systems, and managing electrical circuits. Their ability to function reliably in harsh conditions—exposure to dust, dirt, and extreme temperatures—ensures that construction operations run smoothly and efficiently.

Advantages of Using Rocker Switches for Operational Efficiency

Simplified Control Systems

Ease of Use

One of the most compelling advantages of rocker switches is their ease of use. The simple act of toggling the switch back and forth requires minimal effort, making them suitable for users of all skill levels. This ease of operation is particularly beneficial in industrial settings where swift, uncomplicated control mechanisms are essential for smooth and streamlined processes.

Enhanced Safety Features

Rocker switches prioritize safety through their design. Numerous models are equipped with safety features, such as illuminated indicators that display the on/off status, ensuring operators are consistently informed about the switch’s current state. Furthermore, the design of these switches lowers the risk of unintended activation or deactivation, which helps to reduce potential hazards in industrial settings. These safety improvements collectively contribute to a safer working environment overall.

Durability and Reliability

Resistance to Extreme Conditions

Rocker switches are engineered to withstand extreme conditions, making them ideal for demanding industrial environments. These switches are often manufactured using high-quality materials resistant to corrosion, moisture, and temperature fluctuations. Their robust construction ensures consistent performance and durability, even in the most challenging settings.

Long Lifespan and Low Maintenance

The longevity of rocker switches is another significant advantage. Their simple yet sturdy design means fewer components are prone to wear and tear, translating to a longer operational life and lower maintenance requirements. This reliability reduces the need for frequent replacements or repairs, offering cost savings and uninterrupted productivity in industrial applications.

Energy Efficiency

Power Management Capabilities

Rocker switches also enhance energy efficiency by enabling precise control over electrical circuits. They allow operators to quickly and easily turn off machines or systems when not in use, thereby conserving energy. The efficient power management capabilities of these switches contribute to reduced energy consumption, which is both economically and environmentally beneficial.

Key Considerations When Integrating Rocker Switches

Choosing the Right Type for Your Needs

Evaluating Voltage and Current Ratings

When integrating rocker switches into industrial equipment, it is crucial to select the appropriate type based on voltage and current ratings. Overlooking these factors can result in poor performance or even equipment failure. Ensuring that the chosen switch aligns with the electrical requirements of the application guarantees optimal functionality and safety.

Environmental Factors to Consider

Environmental conditions should be a primary consideration when choosing rocker switches. Factors such as moisture, dust, and temperature extremes can impact switch performance. Selecting switches specifically designed to withstand these environmental challenges ensures reliable operation and longevity, making them suitable for various industrial applications.

Installation Best Practices

Proper Wiring Techniques

Proper wiring is essential for the safe and effective functioning of rocker switches. Adhering to recommended wiring techniques—including secure connections and appropriate insulation—prevents issues such as electrical shorts or malfunctions. Following these best practices ensures the switches operate reliably and enhances overall system integrity.

Ensuring Compliance with Industry Standards

Adhering to industry standards is a crucial factor when integrating rocker switches. These standards typically cover aspects such as safety, performance, and environmental guidelines, ensuring that the switches comply with regulatory requirements. Compliance with these standards not only guarantees legal adherence but also enhances trust in the reliability and safety of the equipment utilized in industrial operations.

Kangerle

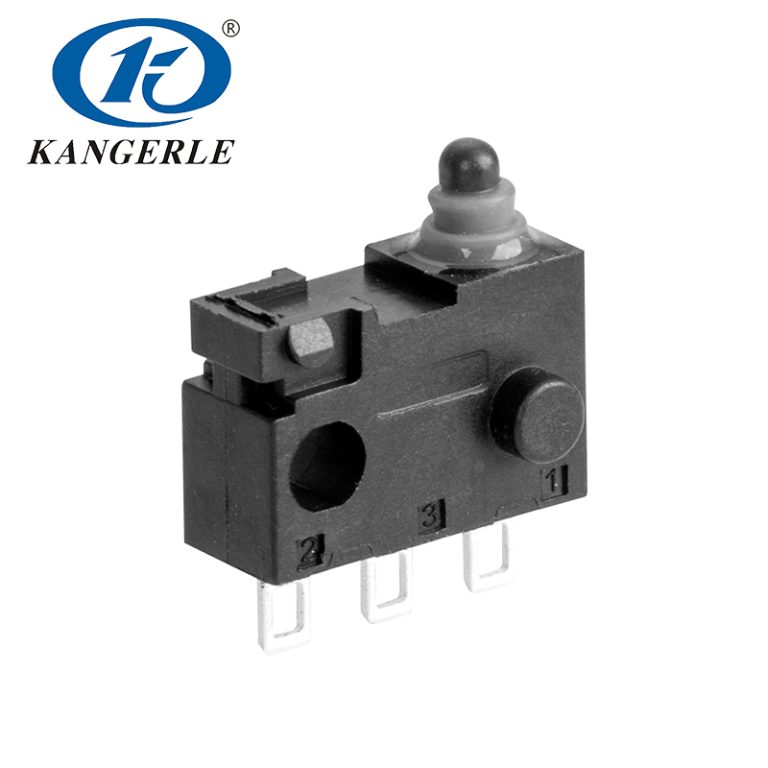

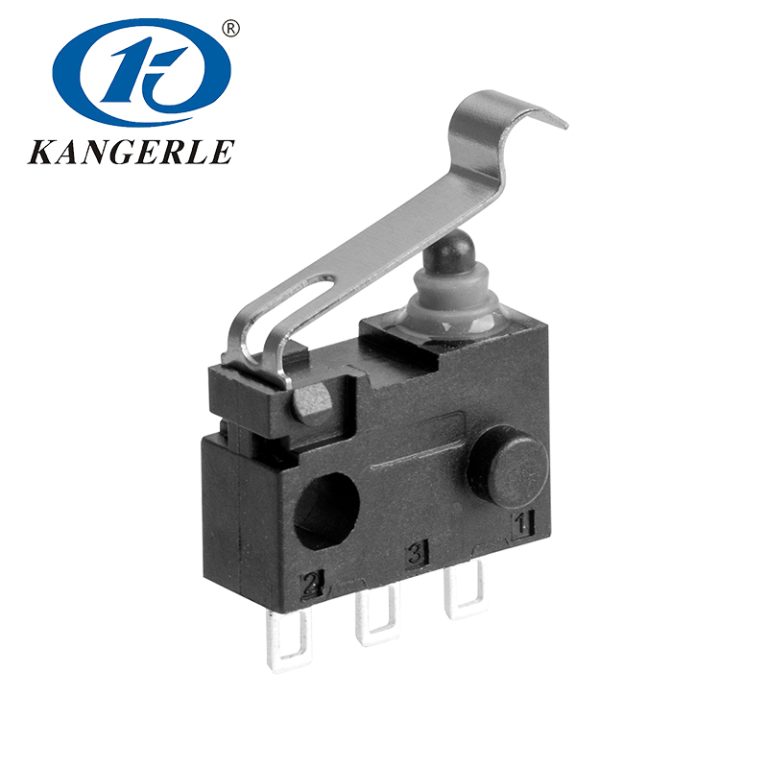

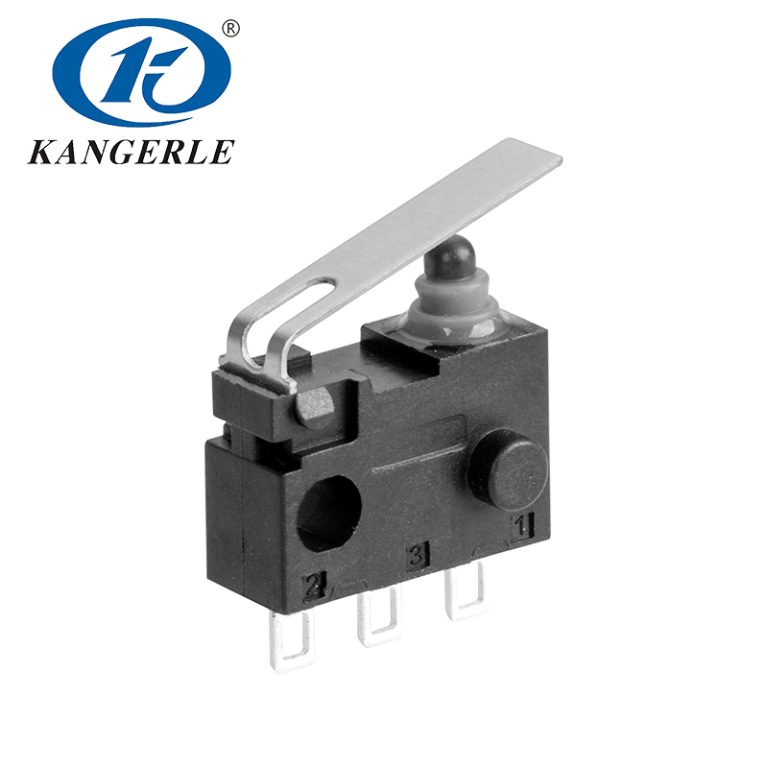

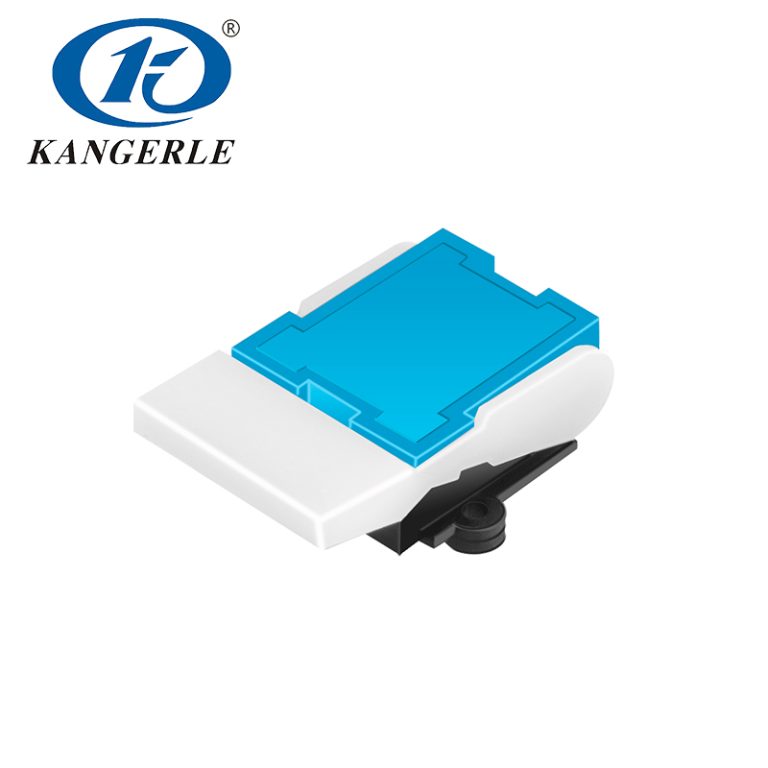

Kangerle is a renowned manufacturer known for its high-quality and durable rocker switches. These switches, also known as boat switches due to their unique shape, are an integral part of various industrial and household applications. They are designed with an intuitive and easy-to-use mechanism, making them a popular choice for many.

One of Kangerle’s standout products is the Rocker Switch KCD1-106N. This switch is known for its high current load capacity and is equipped with different types of terminals. It comes in various types including normal, waterproof, and illuminated, catering to a wide range of needs. This switch is commonly used in electric pancake makers, water dispensers, nebulizers, power tools, oxygen concentrators, industrial equipment, pet appliances, electric fish scalers, hair dryers, and more.

Another notable product from Kangerle is the Rocker Switch KCD2-202D 6P. Like the KCD1-106N, this switch also boasts a high current load capacity and is available in normal, waterproof, and illuminated types. Its versatility and durability make it an excellent choice for various applications.

To sum up, Kangerle’s rocker switches play a crucial role in enhancing operational efficiency within the industry. With their robust load capacity, adaptability, and intuitive design, they stand out as an excellent option for various applications. Opt for Kangerle’s rocker switches to ensure dependable and efficient performance.

Future Trends and Innovations in Rocker Switch Technology

Advanced Materials for Better Performance

The continuous evolution of rocker switches is driven by advances in materials science. The use of high-performance plastics, ceramics, and composite materials significantly enhances the durability and longevity of these switches. These materials are designed to withstand extreme temperatures, moisture, and corrosive environments, ensuring reliable performance even in harsh industrial settings. Furthermore, innovative materials contribute to the reduction of weight and energy consumption, making them more efficient and sustainable. As industries increasingly prioritize sustainability, the shift towards advanced, eco-friendly materials in the manufacturing of rocker switches represents a meaningful step forward.

Integration with Smart Systems and IoT

The integration of rocker switches with smart systems and the Internet of Things (IoT) is another emerging trend. Modern rocker switches are now equipped with sensors and wireless communication capabilities, allowing them to interact with other smart devices and systems. This connectivity enables real-time monitoring and control, enhancing operational efficiency and predictive maintenance. For instance, a smart rocker switch can send alerts to a central system if it detects unusual electrical activity, prompting preventative measures to avoid equipment failure. The fusion of traditional switch technology with cutting-edge IoT solutions represents a significant leap in operational intelligence and automation.

Enhancing Operational Efficiency Through Strategic Use of Rocker Switches

A strategic approach to incorporating rocker switches into industrial systems can lead to remarkable improvements in operational efficiency. By selecting the right type of switches and considering environmental factors and compliance requirements, businesses can ensure optimal performance and safety. Proper installation and maintenance practices further contribute to the reliability and longevity of the switches, reducing downtime and maintenance costs. Moreover, the integration of advanced materials and smart technologies amplifies these benefits, paving the way for more resilient and efficient industrial operations. Using rocker switches strategically allows businesses to enhance productivity, improve energy management, and maintain a safer working environment.