Fundamentals of Rocker Switches and Push buttons

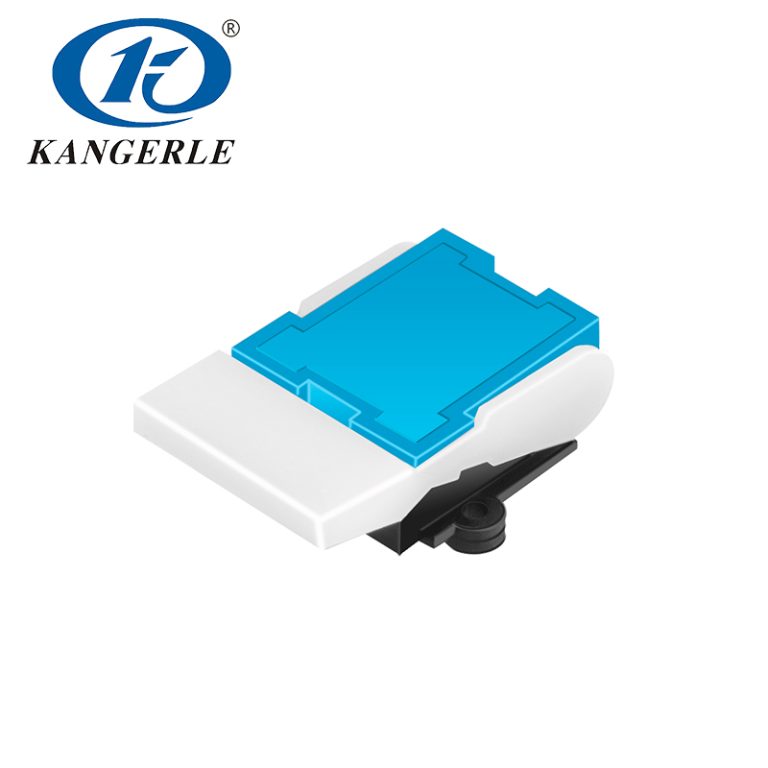

Rocker Switches

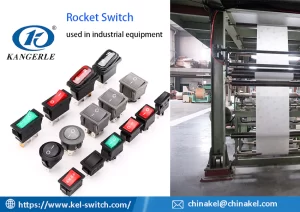

The boat switch or Rocker Switch is known for its shape. It is used to switch between different positions, with a simple press motion It is available in various setups like single pole single throw (SPST) and double pole double throw (DPDT) suitable for diverse purposes The Rocker Switch is becoming more common, in industrial environments because of its user-friendly operation and comfortable design characteristics they are designed to manage usage levels that allow them to be used in devices, like electric pancake makers and industrial equipment as well, as power tools.

In settings, a dependable Rocker Switch can mean the distinction, between operation and possible downtime. Rocker Switches user-friendly nature can decrease the likelihood of errors by operators making them well-suited for use in factories and machinery environments. Kangerle‘s assortment of Rocker Switches, which includes variants makes them suitable, for settings including those exposed to moisture or challenging conditions.

Comprehending Push button Switches

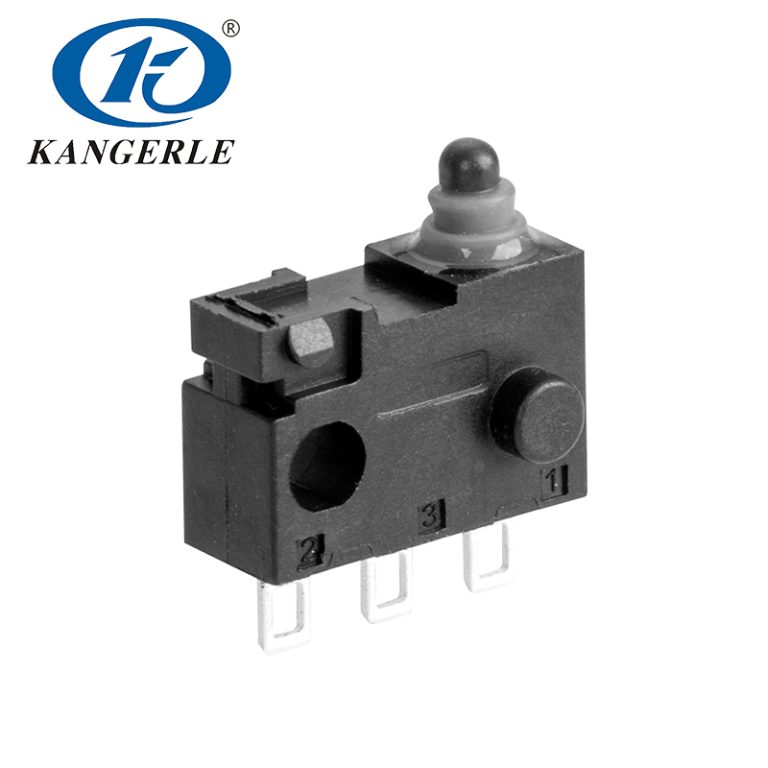

Push button switches provide a way to operate devices by acting as contacts that close the circuit only when pressed down or tapped lightly continuously for engagement purposes compared to Rocker Switches that stay in position until manually changed over time by requiring constant pressure or short taps, for activation functions which can include resets or controlling lightweight equipment Their straightforward design makes them popular choices, in control panels and user interfaces that prioritize simplicity and minimalism.

Push button switches are commonly found in devices because of their design but they may not offer the same durability as more suitable Rocker Switches, for heavy-duty machinery applications that demand superior performance and reliability. The variance, between these switch types extends beyond their functions to include the scenarios where they excel the most. Kangerle’s Rocker Switches provide a user option that works well in settings where easy identification and operation are essential.

When deciding between Rocker Switches and Push button switches for an application choice comes down to what’s needed for the task, at hand, and personal preference too! Knowing the variances can have an impact, on how equipment is designed and runs smoothly in industrial settings. Kangerle has a variety of options available so companies can easily pick Rocker Switches that match their requirements while also guaranteeing that their equipment lasts long and stays sturdy.

Mechanical and Functional Differences

Structural Contrasts

Push button switches have structural designs to suit their specific functions effectively. Rocker Switches usually come in a dual-lever design that allows users to switch between states by pressing one side or the other. This switching action adjusts the components to establish a dependable connection or disconnection, from the power source. On the other hand Rocker Switches operate with a rocking motion triggered by pressing the button often necessitating users to keep pushing the button for continuous action. This basic distinction, in construction results, in uses; Rocker Switches are better suited for situations requiring dependable switching whereas Push button switches are commonly employed in scenarios that call for momentary input.

Operational Dynamics

The way Rocker Switches and Push button switches work highlights their benefits. Where they are best suited for use even better. Rocker Switches function based on a lever system that makes them easy to understand and use for individuals. Being able to determine the switch’s position helps minimize errors during paced tasks. This ease of use is especially crucial, in industries, like manufacturing where swift and accurate responses are essential.

Push button switches require a user interaction approach compared to types of switches due, to their momentary operation nature Users need the training to utilize them efficiently as they cater to transient interactions that may not be ideal, for tasks requiring frequent toggling Potential user errors tend to rise with Push button switches, especially in intricate machinery environments where distractions abound

For organizations to make the switch choice that suits user needs and operational efficiency while considering factors.

Choosing the Right Switch for Industrial Equipment

Choosing the type of switch, for machinery is a vital decision that can have a big impact on how smoothly and safely operations run. When deciding between Rocker Switches and Push button switches it’s important to consider the needs of the job and factors like how weight the switch can handle how often it will be used and how easy it is for users to interact with it. Rocker Switches are great for situations where you need to flip them on and since they make switching, between states quick and clear without any confusion. The evident visual cues improve the dependability of operations by showing operators the status of the switches.

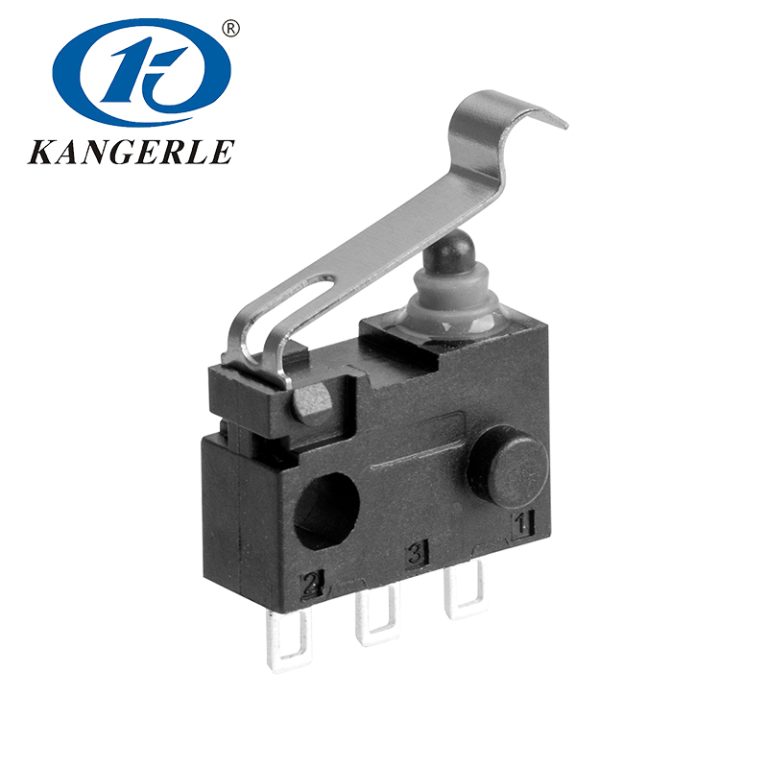

Kangerle rocker switches in Industrial Settings

The Rocker Switches made by Kangerle are designed for uses and are known for their reliable performance and durability. Their range includes styles and load capacities tailored to meet the needs of machinery as well, as specialized equipment such as medical devices. These switches are highly valued in settings where equipment is frequently subjected to demanding conditions due, to their construction.

Furthermore, Kangerle presents waterproof and illuminated choices in their Rocker Switches to cater to settings, as outdoor or high-humidity environments effectively. With the illuminated Rocker Switches offer cues for operators to easily determine equipment status even in dimly lit surroundings or intricate work areas. Understanding the difference between Rocker Switches and Push button switches holds importance, for industrial customers aiming to improve the safety measures and productivity levels of their machinery.

When organizations opt for Kangerle rocker switches they can rest assured that their operational requirements are appropriately addressed, bringing about productivity and safety throughout their operations. The dependable performance, thought-out design, and adaptable use of Kangerle establish it as an ally, in the advancement of industrial machinery.

Practical Benefits for Industrial Usage

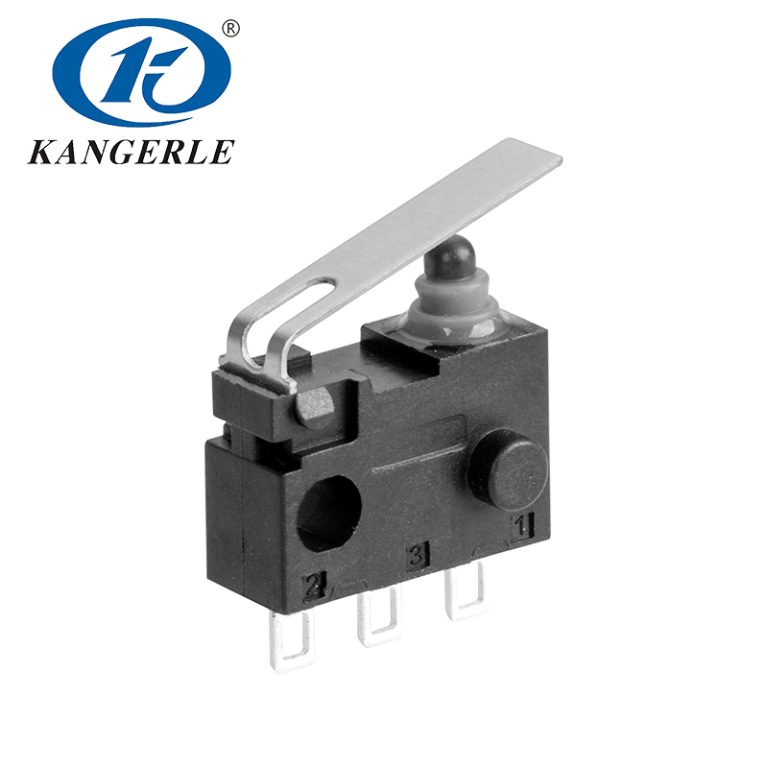

Rocker Switches are made for user convenience, in mind in places with conditions. The design is user-friendly. Allows users to switch easily in situations where they are wearing gloves or when space is limited.Rocker Switches enable intuitive operation by rocking the hand, unlike Push button switches which need precise pressing actions. This is particularly useful, in environments where operators must quickly adapt to changing conditions while staying focused on their tasks.

Also, the Rocker Switches have a signal that makes them user-friendly. Users can easily see whether they are, on or off which helps minimize mistakes. Kangerle’s products guarantee that this visual feedback works well in lighting conditions making them suitable, for use both indoors and outdoors.

Longevity and Reliability in Harsh Environments

Rocker Switches are built tough to work reliably in settings. Kangerle’s Rocker Switches are designed to endure conditions such, as temperatures and exposure to dust and moisture. They can handle loads without wearing out easily thanks to their durability. This means the need for replacements and downtime, in operations where productivity is key.

In comparison to Push button switches which may lack durability and reliability in certain conditions, Rocker Switches are more durable and reliable, for heavy-duty tasks. Rocker Switches are built to withstand use without deteriorating over time. For businesses focusing on lasting and robust equipment Kangerles varied range of Rocker Switches offers an option that meets operational requirements.

Making an Informed Decision

Choosing the switch requires a thorough evaluation of the unique operational requirements at hand. Deciding between rocker and Push button switches depends on the needs of the task. Companies must evaluate aspects, like usage frequency, environment-related factors, and user engagement expectations to select the switch that will optimize their workflow effectively.

When choosing Kangerle Rocker Switches, for use decision-makers can enjoy a selection of products designed to meet different needs in the industry. These switches can be customized to fit equipment requirements helping companies address safety and efficiency concerns, in their operations. By considering the functions of rocker and Push button switches businesses can enhance their performance. Reduce the potential risks linked to equipment malfunctions or incorrect usage.

An Insight into Kangerle‘s Expertise

Kangerle stands out as a provider of switching solutions that cater to different industrial needs by specializing in Rocker Switches, for various applications within the industry sector.

Their dedication to delivering quality and functional products shines through their range of Rocker Switches suitable for both light and heavy-duty usage. The company takes pride in its testing procedures for each switch to ensure notch reliability and safety standards. Kangerle’s Rocker Switches have gained popularity across industries such, as manufacturing, automotive, medical, and consumer electronics showcasing their adaptability and superior performance quality.

It is Kangerle’s product’s feature designs that make it simple for manufacturers to incorporate them into their equipment seamlessly and efficiently. The Rocker Switches from Kangerle offer load capabilities and a range of terminal choices that cater to the unique requirements of their customer’s industries enabling them with practical solutions. The company remains dedicated to staying in innovation to meet the increasing needs of today’s advancing technology landscape.