Components and Design

Understanding the components and design of a push button switch is crucial for comprehending its functionality and selecting the right type for various applications. Let’s break down the external parts and internal mechanisms that make up a push button switch.

External Parts

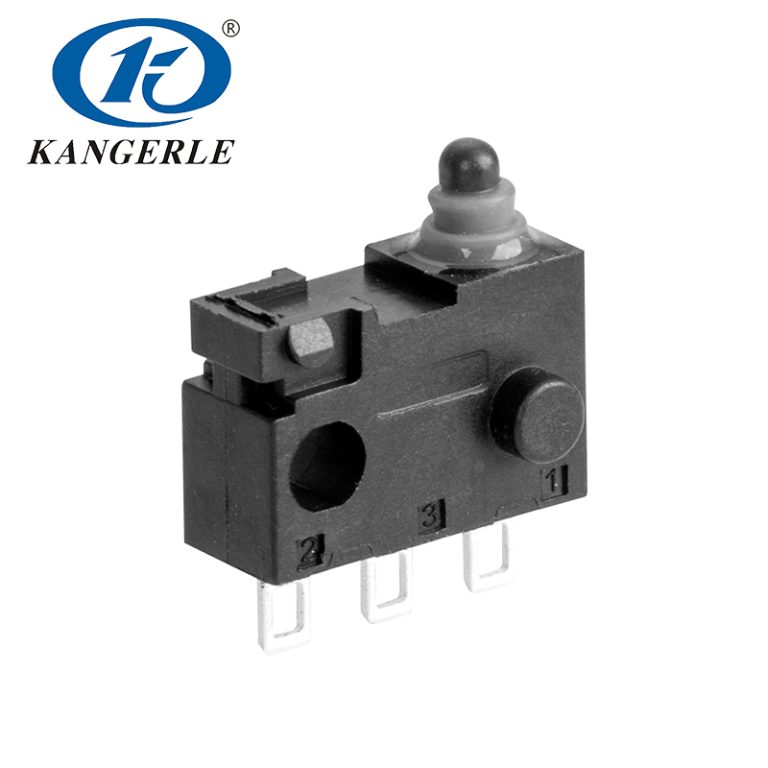

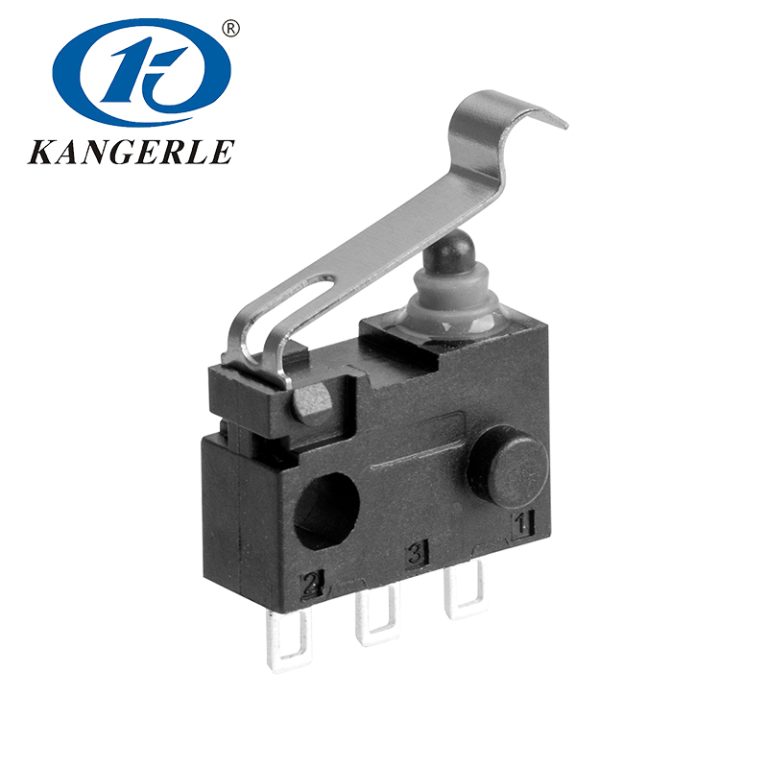

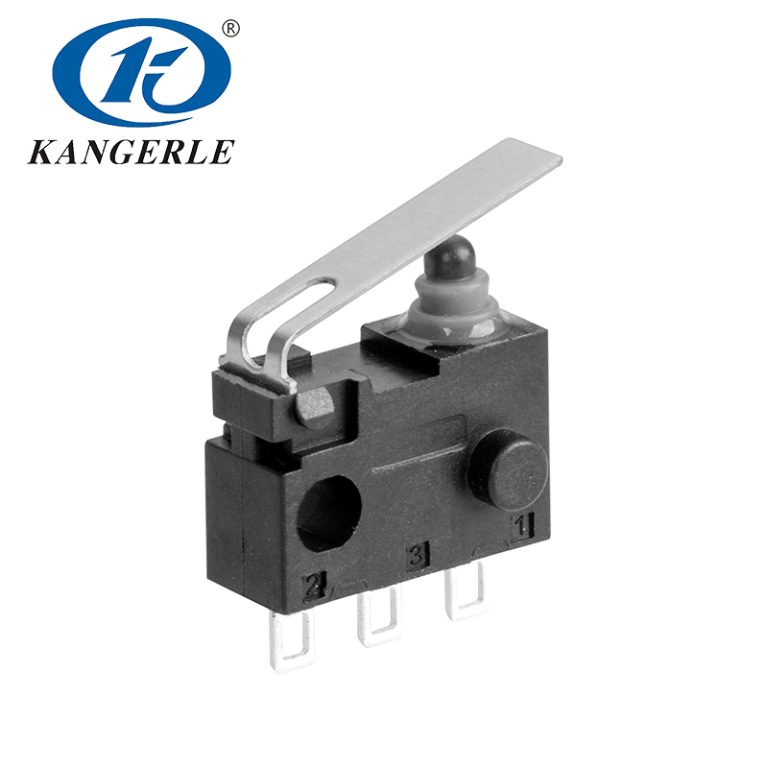

Actuator

The actuator is the part of the push button switch that is visible to the user and is pressed to operate the switch. Typically made from durable plastic or metal, the actuator can come in various shapes, sizes, and colors to suit different aesthetic and functional requirements. Some actuators are also designed with tactile feedback mechanisms, allowing the user to feel a click or resistance when the button is pressed, ensuring a more reliable operation.

Bezel

The bezel is the outer frame or casing that houses the actuator and the internal components of the push button switch. It provides structural support and protection against external damage and environmental factors such as dust and moisture. Bezels can be designed to be waterproof or dustproof, depending on the intended application environment. The bezel also plays a key role in the aesthetic design of the push button switch, often matching the style and design of the device it is installed in.

Internal Mechanisms

Contacts

The contacts in a push button switch are critical for the switch’s fundamental operation. When the actuator is pressed, it moves the contacts into a position that either opens or closes the circuit. These contacts are usually made from conductive materials like brass, copper, or a silver alloy, chosen for their excellent electrical conductivity and resistance to wear and corrosion. The precise engineering of the contacts ensures reliable performance and longevity of the switch, reducing the likelihood of electrical glitches.

Springs

Springs are essential components that contribute to the movement of the actuator and the contacts. In momentary push button switches, the springs return the actuator and contacts to their original position once the button is released. The spring’s tension and material need to be meticulously selected to provide the right balance between ease of use and operational reliability. A well-designed spring system ensures that the switch can endure numerous cycles of pressing and releasing without mechanical failure.

Applications in Various Industries

Push button switches are not just limited to household appliances; their utility spans across various industries. The ruggedness, reliability, and versatility of push button switches make them indispensable in multiple sectors, including consumer electronics, industrial machinery, and the automotive industry.

Consumer Electronics

Push button switches are everywhere in the world of consumer electronics. You’ll spot them on your remote controls, gaming consoles, and smartphones anytime you need to press something to make it work. Because we all want our gadgets to be sleek and dependable, there’s always a push for cooler designs with these buttons. And let’s not forget—these little guys have to hold up under tons of use without failing us! So yeah, there’s some pretty tight quality control going on behind the scenes.

Industrial Machinery

Industrial machinery often relies on push button switches for both operational and safety purposes. These switches are used to start and stop machinery, activate specific functions, and serve as emergency stop buttons. The harsh environments in which industrial machinery operates require push button switches to be exceptionally durable, resistant to moisture, dust, and mechanical wear. They must also comply with industrial safety standards to ensure reliable performance and protect operators from hazards.

Automotive Sector

In the automotive sector, push button switches are integral to vehicle functionality and user experience. From dashboard controls to window operations and ignition start systems, push button switches enhance the convenience and safety of modern vehicles. Automotive switches need to be resilient to temperature variations, vibrations, and electromagnetic interference commonly encountered in vehicles. High reliability and ease of use are critical, as any failure could lead to significant safety issues or inconveniences.

How to Select the Right Push Button Switch

Selecting the right push button switch for a particular application involves several critical considerations. The suitability of a switch depends on multiple factors, including its electrical rating, environmental conditions, and the supplier’s reliability.

Parameters to Consider

Electrical Rating

The electrical rating is one of the primary factors to consider when selecting a push button switch. This rating includes the maximum current and voltage that the switch can handle safely. Using a switch with an inappropriate electrical rating can lead to failures, overheating, or even hazards such as electrical fires. It is vital to match the switch’s rating to the specific requirements of the application to ensure safe and efficient operation.

Environmental Conditions

Environmental conditions play a significant role in determining the appropriate push button switch. Factors such as temperature ranges, exposure to moisture, dust, chemicals, and mechanical impacts need to be considered. For instance, switches used in outdoor or industrial environments may require higher ingress protection (IP) ratings to withstand harsh conditions. Selecting a switch designed for the specific environmental challenges of its application site ensures longevity and reliable performance.

Supplier Selection

Choosing a reliable supplier is as important as selecting the appropriate switch. Reputable suppliers provide detailed specifications, compliance with industry standards, and robust customer support. Collaborating with a supplier with a proven track record ensures that the switches are of high quality and meet the required specifications. Additionally, a good supplier will offer after-sales support, including maintenance tips and troubleshooting assistance, which are invaluable for long-term reliability and performance.

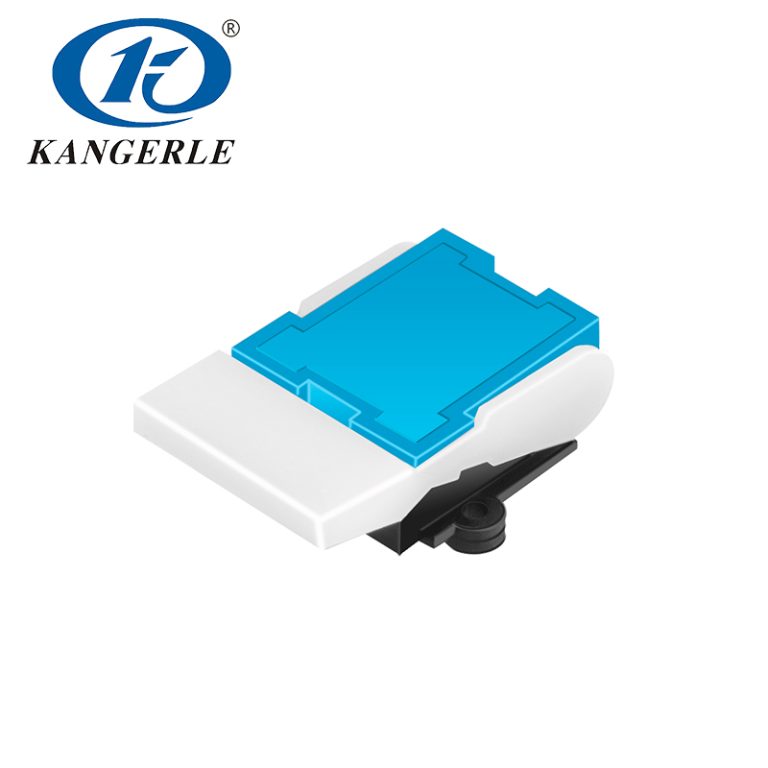

Check out Kangerle Electronics, the go-to brand in the electronic components scene. They’ve got a killer lineup of metal push button switches that are perfect for all sorts of uses. These bad boys come with a strong metal shell and a super responsive button, making them way more durable than plastic ones. Plus, they look sleek and give you that satisfying click feeling.

These switches aren’t just pretty faces either—they’re waterproof, dustproof, and can handle some serious wear and tear. So yeah, they’re great for tough environments where reliability is key.

Kangerle’s got options galore with different series and specs to choose from. And don’t worry about setup–their plugins make it a breeze to get things running smoothly.

You’ll find sizes like 12mm up to 30mm with choices between momentary or maintained operation. Some even have built-in LEDs if you want something lit! Whether it’s home appliances, industrial controls, power gear, comm devices, medical tools—you name it—these switches do it all. Versatile? You bet!

Maintenance and Troubleshooting Tips of Push Button Switches

Regular maintenance and timely troubleshooting are essential to keep push button switches functioning optimally. Proper care enhances the switch’s performance and extends its lifespan, minimizing downtime and costs associated with switch failures.

Maintenance involves cleaning the switch regularly to remove dust and debris that could obstruct its operation. Using appropriate cleaning agents that do not corrode the switch’s materials is crucial. It is also important to periodically check for signs of wear and tear or damage to the actuator, bezel, contacts, and springs.

Troubleshooting commonly involves identifying issues such as poor electrical contacts, sticking actuators, or mechanical failures. Replacing worn-out contacts or springs can resolve operational inconsistencies. In cases of complex issues, consulting the supplier’s support services can provide effective solutions and prevent further damage.

By understanding how a push button switch works and the factors to consider when selecting, maintaining, and troubleshooting these components, users can ensure reliable and efficient performance in their applications.