Micro switches, also known as snap action micro switches, are integral components in various home appliances. These small and versatile switches play a significant role in ensuring the functionality and safety of appliances like coffee machines, ice makers, microwave ovens, rice cookers, and more. The ability to customize micro switches to suit specific appliance requirements has become a game-changer in the home appliance industry. Kangerle Electronics has more than 20 years of manufacturing micro switches, and our experienced engineers can provide you with a micro switch solution for home appliances.

1. Tailoring to Appliance Switch Design

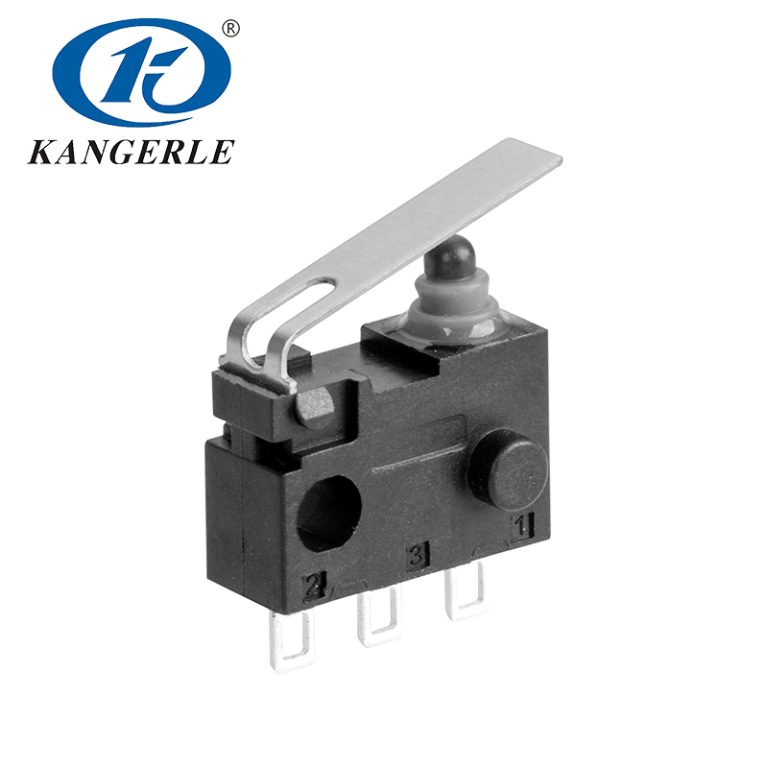

One of the primary reasons for customizing micro switches in home appliances is to align them with the specific design and dimensions of the appliance. Home appliances come in various shapes and sizes, and each one has unique operational requirements. Customization allows manufacturers to design micro switches that fit seamlessly into the appliance’s structure, ensuring a smooth user experience.

For example, a washing machine might require a micro switch with a specific operating lever length to detect the closure of the lid or door. Customization ensures that the micro switch’s actuator is neither too long nor too short, ensuring precise operation and preventing any mishaps during the appliance’s use.

General parameters for home appliance micro switch customization

1. Voltage and Current Ratings

Home appliances vary in their electrical specifications. Customizing micro switches allows manufacturers to select the appropriate voltage and current ratings for their specific appliance. This ensures that the micro switch can handle the electrical load without overheating or causing safety hazards.

In the case of a microwave oven, for instance, the door micro switch must be customized to handle the high voltage and current associated with the microwave’s operation. Customization ensures that the micro switch can safely interrupt the circuit when the door is opened, preventing microwave radiation leakage.

2. Temperature and Environmental Considerations

Different home appliances operate in diverse environmental conditions. Refrigerators, for instance, need to function in a cold, humid environment, while dishwashers are exposed to high temperatures and moisture. Customized micro switches can be designed with materials and coatings that are resistant to specific environmental factors.

For a dishwasher’s detergent dispenser, a micro switch may need to endure exposure to hot water and cleaning agents. Customization allows for the selection of materials that can withstand these conditions, ensuring the micro switch’s longevity and reliability.

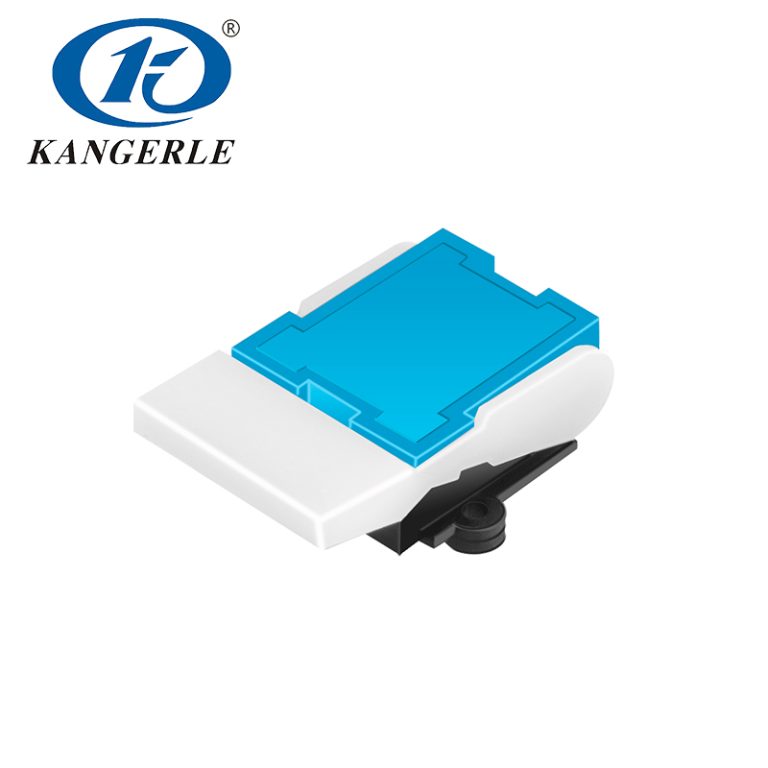

3. Operating Force and Durability

The actuation force required for a micro switch to activate is a critical consideration in appliance design. Customization allows manufacturers to tailor the actuation force of micro switches to meet the ergonomic and functional requirements of the appliance.

In a blender, for example, a micro switch that controls the blending action needs to be sensitive enough to respond to the user’s touch but not so sensitive that it activates unintentionally. Customization allows for adjustments in actuation force to achieve the desired level of sensitivity.

4. Safety and Regulatory Compliance

Safety standards and regulations for home appliances vary by region and type. Customization enables manufacturers to design micro switches that comply with these safety standards. This is particularly crucial in appliances where user safety is paramount, such as gas stoves and water heaters.

A gas stove’s burner control micro switches, for instance, must meet specific safety standards to prevent gas leaks. Customization ensures that the micro switches are designed to meet these safety requirements and provide peace of mind to consumers.

Case examples: Kangerle customized micro switches for home appliance

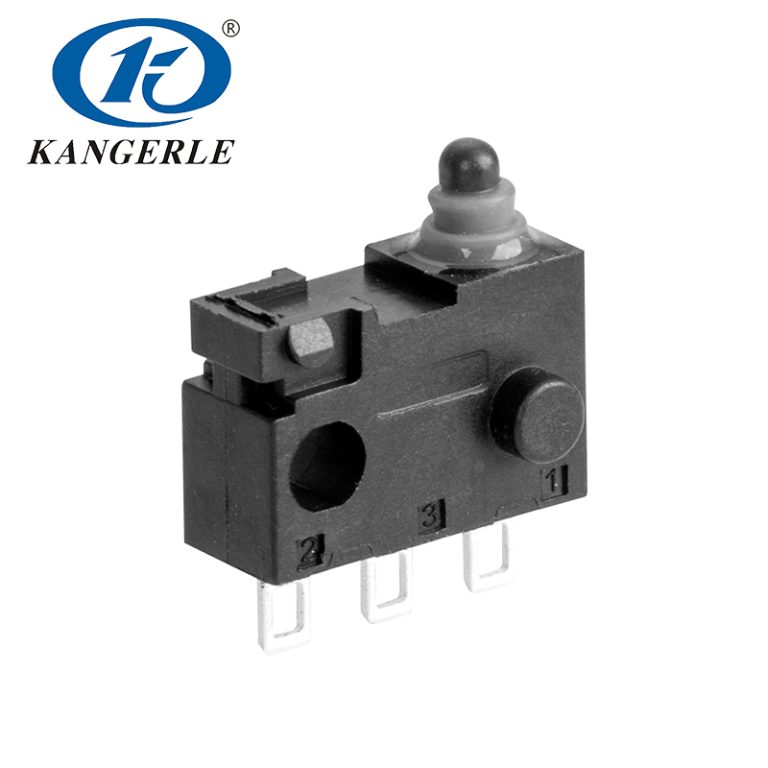

1. Air fryer micro switch KW3-10C-K-6Z

The air fryer has quickly become the top favorite of kitchen appliances since its introduction. The competition between brands is also quite fierce. Nowadays, consumers pursue large cavity volumes and good product quality, which makes many air fryer manufacturers encounter a problem in the selection of a micro switch.

We redesign the direction of the switch’s terminal cause there is no much room for mounting in an air fryer. The design of our KW3 down-bend terminals successfully meets the requirements of maximizing the compression of the internal circuit board and component space. Customers can choose conventional straight-in terminals or down-bend terminals according to their own product specifications.

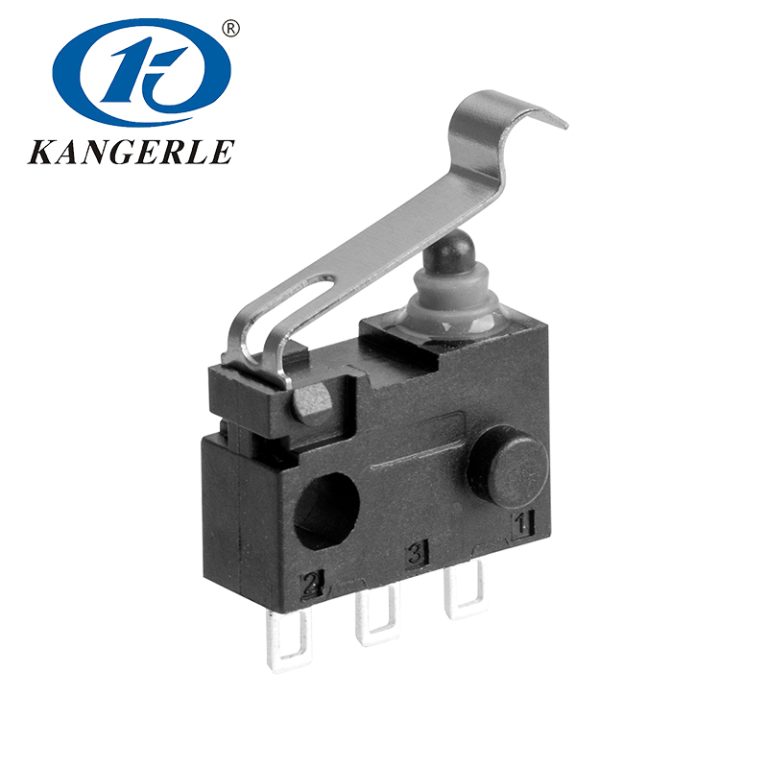

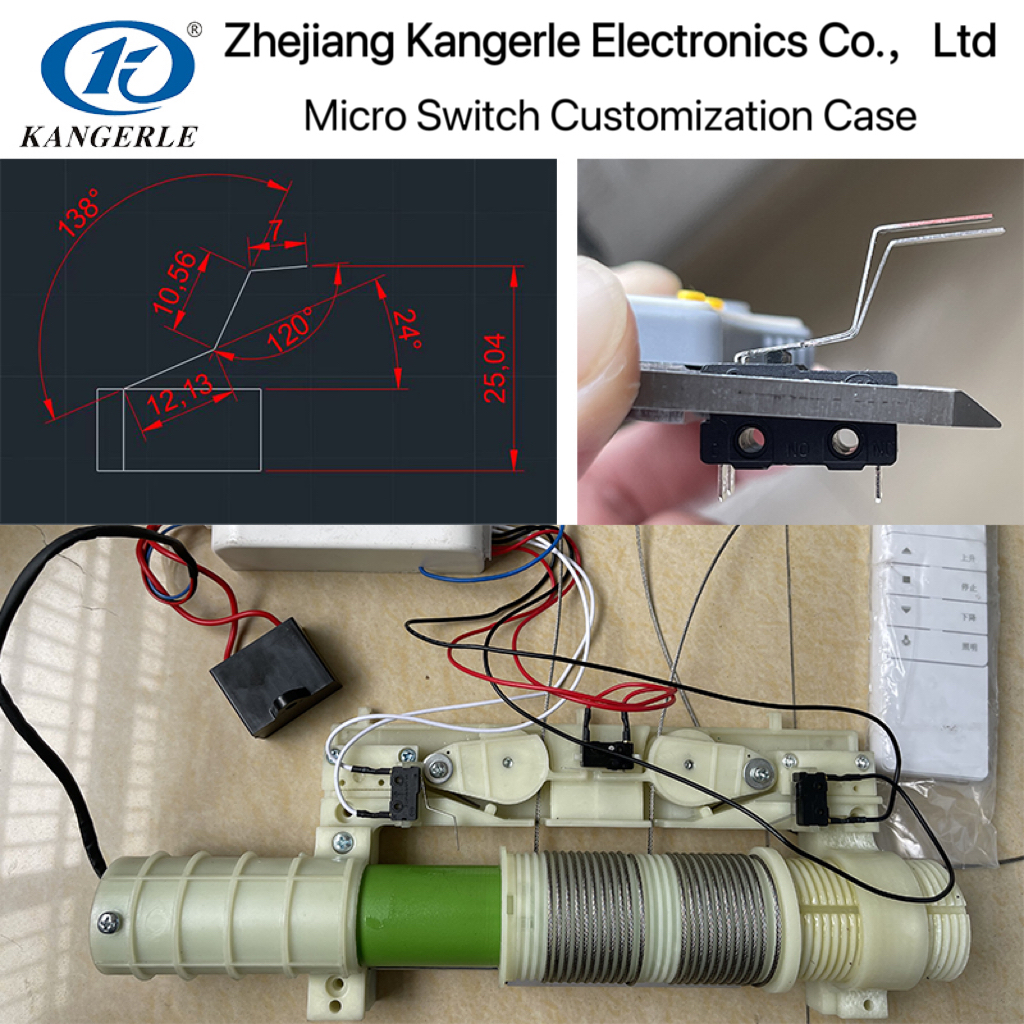

2. Customized micro switch used in electric drying rack

Electric drying racks have become increasingly popular in modern households for their convenience and energy-efficient drying solutions.

A customer from a home appliance manufacturer found there is not a suitable micro switch for his electric drying racks. Regular micro switches on the market can not fit well. Our engineer designs a new mold according to his requirements for products. After getting free samples from our company, they immediately install switches for testing. It was found that there is a part of this micro switch that needs further adjustment. We cooperate to modify the mold and make new samples for customer evaluation. Finally, they passed the test. After several small-batch trials, mass production was successfully achieved!

As you can see, the customization of micro switches in home appliances is essential for ensuring seamless integration, safety, and optimal performance. No matter what your product is, as long as you have customized needs. Kangerle micro switch company can tailor these tiny components to meet the unique requirements of each appliance. From design and electrical specifications to after-sales service, our engineers will provide a one-stop switch solution for your applications. Any questions about our customization, please visit Kangerle official website for more details: https://www.kel-switch.com/.