In the realm of technological advancements, the quest for seamless control has become paramount. Push buttons emerge as the unsung heroes, offering a tangible link between humans and machines. These unassuming switches, whether made of plastic or metal, play a pivotal role in our daily interactions with technology. With a simple press, they empower us to navigate complex systems effortlessly. Today, as industries embrace automation and safety regulations tighten, the significance of push buttons only grows. Let’s delve into how these unassuming components are shaping our digital landscape.

The Mechanics of Push Buttons

In the realm of technological control, push buttons stand out as essential components that facilitate seamless interactions between individuals and machines. Whether they are made of metal or plastic, these simple but important switches are a big part of making it easy to use complicated systems. Knowing how push buttons work on the inside helps you see how important they are in current technology.

How Push Buttons Work

When exploring the functionality of push buttons, it’s vital to distinguish between two primary types: Normally Open (NO) and Normally Closed (NC). A push button labeled as Normally Open completes an electrical circuit when activated, allowing current to flow through. On the other hand, a Normally Closed push button breaks the circuit upon activation, interrupting the current flow. This distinction is fundamental in various applications where precise control is necessary.

Delving deeper into push button mechanisms reveals another critical differentiation: Maintained vs Momentary switches. Maintained push buttons lock into position once pressed, maintaining their state until pressed again. In contrast, Momentary push buttons return to their original state immediately after release. This distinction influences how users interact with devices and machinery, offering flexibility in operation based on specific requirements.

Materials and Design

The choice between plastic and metal for push button construction impacts both durability and reliability. Plastic push buttons are lightweight and cost-effective, suitable for consumer electronics like smartphones and tablets due to their ease of customization. Conversely, metal push buttons offer enhanced durability and a premium feel, making them ideal for industrial settings where robustness is paramount.

In essence, understanding the mechanics behind push buttons unveils their versatility and adaptability across various technological domains. Whether it’s navigating your smartphone effortlessly or ensuring precise control in industrial machinery, these unassuming switches play a pivotal role in shaping our digital landscape.

Applications in Modern Technology

In the realm of modern technology, push buttons find extensive applications across various domains, from consumer electronics to industrial and commercial sectors. These unassuming yet crucial components serve as the bridge between human interaction and machine functionality, enabling seamless control and operation.

Consumer Electronics

Smartphones and Tablets

In the fast-paced world of consumer electronics, push buttons play a vital role in enhancing user experience and device functionality. When you interact with your smartphone or tablet, every touch of a push button initiates a specific action, whether it’s unlocking your screen or adjusting the volume. The tactile feedback provided by these switches ensures that each press is both responsive and intuitive.

Home Appliances

Beyond handheld devices, push buttons have seamlessly integrated into our daily lives through home appliances. Imagine effortlessly setting the timer on your microwave or selecting a wash cycle on your washing machine—all made possible by these unobtrusive yet indispensable switches. With their straightforward operation and reliability, push buttons simplify household tasks and enhance convenience.

Industrial and Commercial Uses

Machinery Control

In industrial settings, precision and efficiency are paramount, making push buttons a cornerstone of machinery control systems. Whether it’s starting a production line or halting operations in case of emergencies, these switches offer operators immediate control over complex equipment. The durability of metal push buttons ensures continuous performance even in demanding environments, safeguarding productivity.

Security Systems

Security is non-negotiable in commercial establishments, where access control and surveillance are critical aspects of operations. Push buttons serve as access points for authorized personnel, granting entry with a simple press. Additionally, these switches are integrated into security systems to trigger alarms or emergency protocols swiftly when needed. Their reliability under pressure makes them indispensable components in ensuring safety and protection.

While technology keeps getting better and better at a fast rate, push buttons are still the most reliable and flexible way for people and machines to work together in a wide range of situations. From making the user experience better in smartphones to letting precise control in industrial machinery, these small but powerful switches continue to change the way we use technology.

Benefits of Push Buttons

Ease of Use

In the realm of technological control, push buttons reign supreme for their unparalleled ease of use. With a simple press, users can effortlessly navigate through intricate systems, making them ideal for both novice and experienced individuals. The straightforward operation of push buttons simplifies interactions with various devices, ensuring a seamless user experience.

Simple Operation

The simplicity of push buttons lies in their intuitive design and functionality. Each press does a certain thing, like turning on a device or changing the settings. With this simple process, there’s no need for complicated steps or directions, so people can use technology without any problems. The direct correlation between pressing a push button and immediate feedback makes them a user-friendly choice across different applications.

Quick Response

One remarkable feature of push buttons is their swift response time. Upon activation, these switches instantly initiate the intended function without any delay, providing users with real-time control over devices. Whether it’s starting a machine in an industrial setting or unlocking a smartphone screen, the quick response of push buttons ensures efficient operation and enhances overall productivity.

Versatility and Adaptability

The versatility of push buttons extends beyond their ease of use to encompass a wide range of applications across diverse industries. These simple buttons are flexible enough to meet a wide range of needs, from those in household electronics to those in industrial machinery. Their ability to be changed means they can work with a lot of different systems, which makes them essential to current technology.

Wide Range of Applications

The widespread use of push buttons underscores their versatility in modern technology. In everyday items like remote controls, elevators, and ATMs, these switches are the main ways that users can connect with the gadget. Moreover, in specialized industries such as healthcare and automotive manufacturing, push buttons play crucial roles in ensuring precision and efficiency in operations.

Customization Options

One key advantage of push buttons is the ability to customize their design and functionality based on specific requirements. Manufacturers can tailor the size, shape, color, and tactile feedback of these switches to suit different applications. Whether it’s designing an ergonomic control panel for medical equipment or implementing safety protocols in industrial settings, customized push buttons offer enhanced usability and reliability.

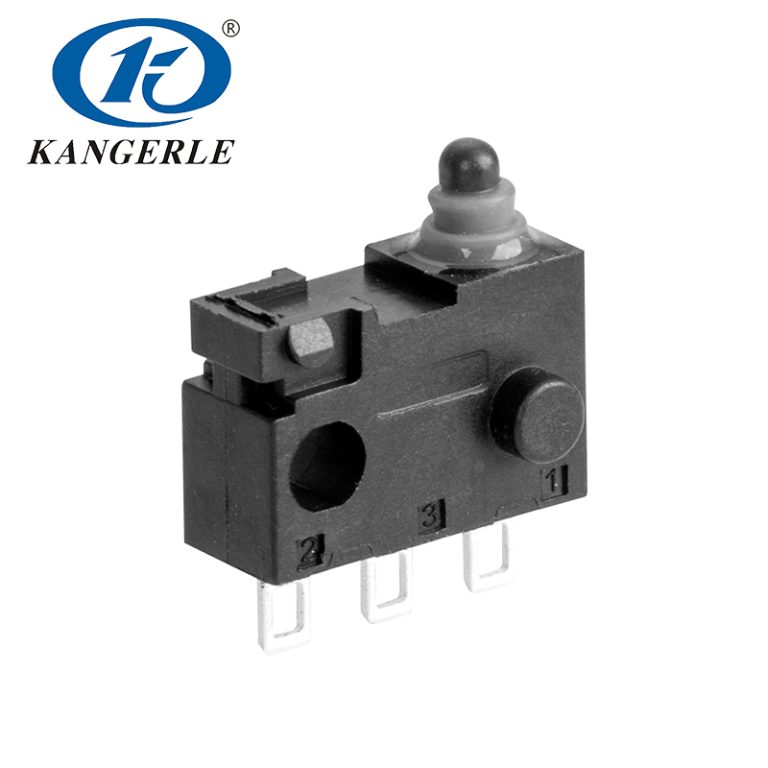

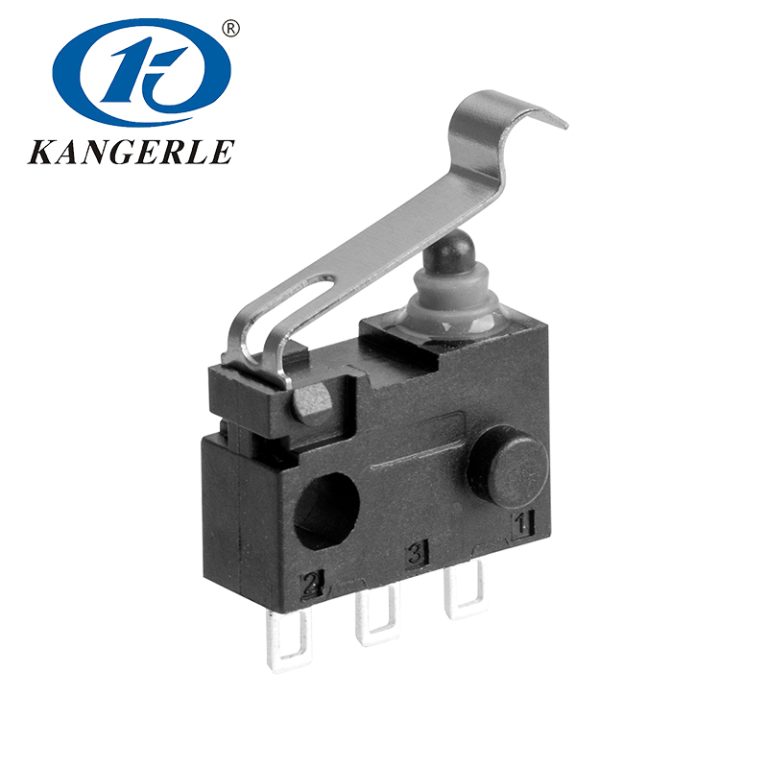

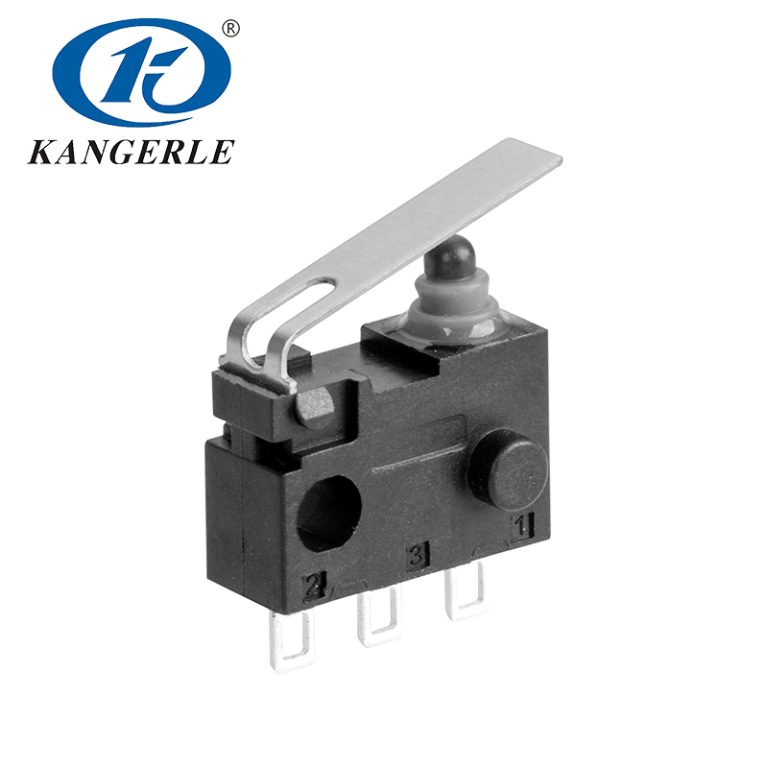

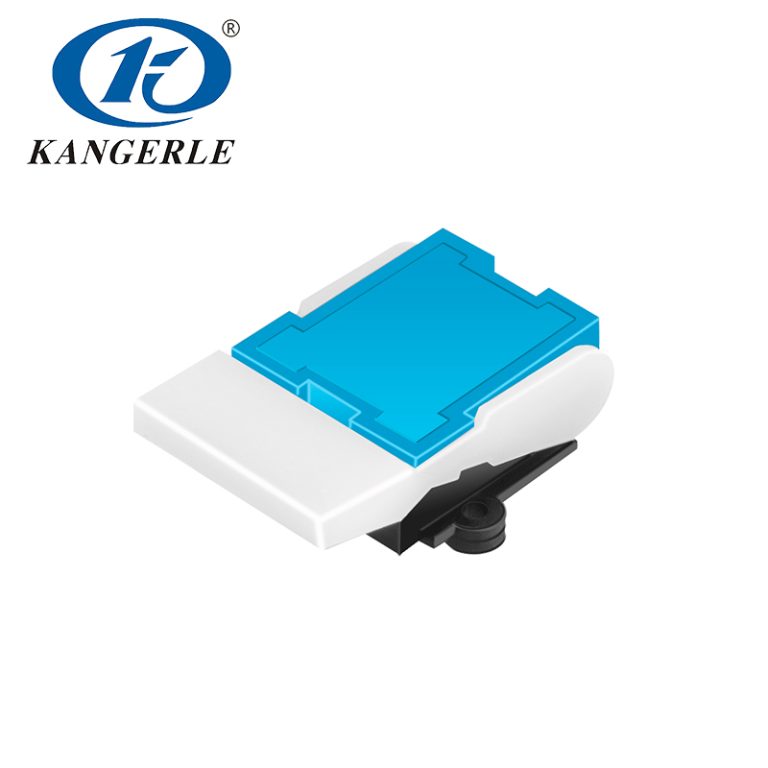

ZHEJIANG KANGERLE ELECTRONICS CO. LTD is a well-known and trusted business that makes electronic components. They have been making high-quality electronic switches for over 20 years. Some of the switches they make are micro switches, detector switches, limit switches, rocker switches, slide switches, tact switches, and push button switches. The company has a group of experienced engineers, technicists, and top managers who know how to make switches that work well and last a long time.

A well-known company called ZHEJIANG KANGERLE ELECTRONICS CO. LTD makes and sells mechanical parts, and they have a lot of high-quality push button switches for sale. Their push button switches are designed with a metal shell and a button, making them more durable and capable of withstanding external forces compared to plastic button switches. They are waterproof, dustproof, and corrosion-resistant, enabling them to function reliably in harsh environments.

As technology continues to evolve rapidly, the benefits of push buttons remain steadfast in providing users with intuitive control and seamless interactions across various domains. Because they are flexible, easy to use, respond quickly, and can be customized, they are essential parts that connect what people input and what machines output.

The realm of technological control hinges on the unassuming yet indispensable push buttons. These switches are what make it possible for people and machines to work together smoothly, whether they’re in household electronics or heavy machinery. Their flexibility goes beyond common uses and will affect how technology and safety rules are used in the future. As industries embrace smart manufacturing practices and prioritize workplace safety, the demand for advanced signaling devices like push buttons continues to soar. The constantly changing nature of technological progress shows how important these basic but game-changing parts are for promoting innovation and efficiency in many areas.