Connectors in Wearable Technology

Definition and Importance of Connectors

Connectors are electromechanical components that join electronic circuits, typically through mechanical assembly. In the realm of wearable devices, they are indispensable in ensuring that all parts of the device can communicate efficiently. Their importance lies not only in linking various electronic components but also in enhancing the reliability and durability of these devices. Without robust connectors, wearables would be prone to frequent failures and reduced lifespans.

Types of Connectors Used in Wearable Devices

Wearable devices utilize a variety of connectors to meet different needs and requirements. These include board-to-board, wire-to-board, and cable connectors. Board-to-board connectors are often used for internal connections, providing high-density electrical pathways. Wire-to-board connectors, on the other hand, are crucial for linking the device’s internal circuits to external peripherals. Cable connectors are typically employed for charging and data transfer purposes. Each type of connector is chosen based on specific criteria such as space constraints, durability, and performance requirements.

Enhancing Component Interconnectivity

Role of Connectors in Signal Integrity

Signal integrity is vital for the accurate and reliable operation of wearable devices. Connectors play a pivotal role in maintaining signal integrity by minimizing signal loss and ensuring consistent performance. High-quality connectors are designed to reduce interference and noise, which can adversely affect the performance of sensitive electronic components. By providing a stable connection, these connectors help wearables deliver precise readings and reliable data transmissions.

Facilitating Efficient Power Distribution

Efficient power distribution is another critical aspect of wearable technology that connectors help facilitate. In a compact device, where space is limited, connectors must ensure that power is distributed efficiently without causing excessive heat or energy loss. Good quality connectors are engineered to handle the power demands of wearable devices, ensuring that each component receives the necessary power to function optimally. This efficient power handling contributes to the overall performance and battery life of wearable gadgets.

Durability-Boosting Features of Wearable Device Connectors

Moisture and Dust Resistance

Wearable devices are often exposed to harsh environmental conditions, necessitating connectors that can withstand moisture and dust.

Sealing Mechanisms

Advanced sealing mechanisms are employed in connectors to protect against moisture ingress. Seals made from materials like rubber or silicone create barriers that prevent water from penetrating the device’s inner components. This is particularly important for devices that need to maintain functionality in wet conditions or underwater.

Material Choices

Material choices for connectors also play a significant role in enhancing durability. Using corrosion-resistant metals and high-strength plastics ensures that the connectors can endure exposure to moisture and dust without degrading over time. These materials maintain their integrity under various environmental stresses, thereby enhancing the overall durability of the wearable device.

Flexibility and Stress Relief Solutions

The flexible nature of wearable devices means that their connectors must be designed to handle continuous movement and bending. Flexibility is crucial to prevent breakage and ensure long-term reliability.

Stress relief solutions are incorporated in connector designs to handle mechanical strains. These can include specially designed strain relief boots or flexible cables that absorb the stresses and prevent damage to the connectors themselves. By incorporating such solutions, manufacturers ensure that the connectors remain intact and functional even under frequent use and movement, directly contributing to the longevity of wearable devices.

In conclusion, connectors are integral to the durability and performance of wearable devices. By ensuring robust interconnectivity, efficient power distribution, and resistance to environmental factors, they play a pivotal role in enhancing the lifespan and reliability of wearables. Understanding the significance of these tiny yet vital components can provide valuable insights into the design and functionality of modern wearable technology.

Innovations in Connector Technology for Wearable Devices

Miniaturization and Space Efficiency

One of the primary advancements in connectors for wearable devices is miniaturization. As wearable technology becomes more sophisticated and feature-rich, the need for smaller and more efficient connectors has increased. Miniaturized connectors not only save space but also contribute to the overall lightweight and compact design of the wearables. Despite their smaller size, these connectors are engineered to maintain high performance and reliability. The challenge lies in preserving the durability and functionality within a compact form factor, ensuring that they meet the rigorous demands of daily use.

Space efficiency goes hand in hand with miniaturization. In the confined interiors of wearable devices, there’s limited room for larger components. Space-efficient connectors are designed to fit into these tight spaces without compromising on the device’s performance. This innovation is crucial for integrating multiple functions into wearables while maintaining ergonomic designs. By optimizing the internal layout, these connectors enable manufacturers to pack more features into smaller, sleeker devices.

Advanced Materials and Coatings

Another significant innovation in connectors is the use of advanced materials and coatings. These advancements are particularly important in enhancing the durability and longevity of wearable devices. Materials like high-performance plastics, corrosion-resistant metals, and advanced ceramics are commonly used to manufacture connectors. These materials provide robust mechanical properties and resistance to environmental factors such as moisture, dust, and temperature fluctuations.

Coatings also play a pivotal role in improving the performance and durability of connectors. Specialized coatings can offer additional protection against wear and tear, corrosion, and thermal stress. For example, gold or nickel plating on connectors can enhance conductivity and prevent oxidation, ensuring reliable performance over time. By utilizing such advanced materials and coatings, manufacturers can produce connectors that withstand the harsh conditions wearable devices are often exposed to.

Application Scenarios: Everyday Impact of Durable Connectors

Fitness Trackers and Smartwatches

Daily Wear and Tear Considerations

Fitness trackers and smartwatches are subjected to constant motion and physical stress, making durable connectors a necessity. These devices are worn daily, exposed to sweat, skin oils, and varying environmental conditions. Connectors in these wearables must endure frequent plugging and unplugging for charging and data transfer, as well as resist wear and tear from daily usage. High-quality connectors ensure that despite these challenges, the devices remain functional and reliable over an extended period.

Outdoor Sports and Activities

Wearable devices used for outdoor sports and activities face even harsher conditions. Whether it’s hiking, running, cycling, or water sports, these wearables need connectors that can withstand extreme environments. This includes exposure to dirt, mud, water, and varying temperatures. Durable connectors with robust sealing mechanisms and corrosion-resistant materials are essential in these scenarios. They ensure that the wearables continue to operate accurately and reliably, providing users with critical data and functionality during their activities.

Medical Wearables

Long-Term Usage and Patient Safety

Medical wearables, such as continuous glucose monitors, heart rate monitors, and other health tracking devices, require connectors to be exceptionally durable and reliable. These devices are often worn for extended periods, and their performance directly impacts patient health and well-being. Connectors used in medical wearables must maintain strong, reliable connections to ensure accurate data transmission and device functionality. Any failure in these connectors could compromise patient safety, making durability a top priority.

Hygiene and Cleaning Requirements

In medical applications, hygiene is of paramount importance. Connectors in medical wearables must be designed to withstand regular cleaning and sterilization without deteriorating. This includes resistance to cleaning agents, moisture ingress, and biological contaminants. Advanced materials and coatings that are easy to clean and resistant to microbial growth are employed to meet these stringent hygiene requirements. Durable connectors ensure that medical wearables can be maintained in a sanitary condition, safeguarding patient health.

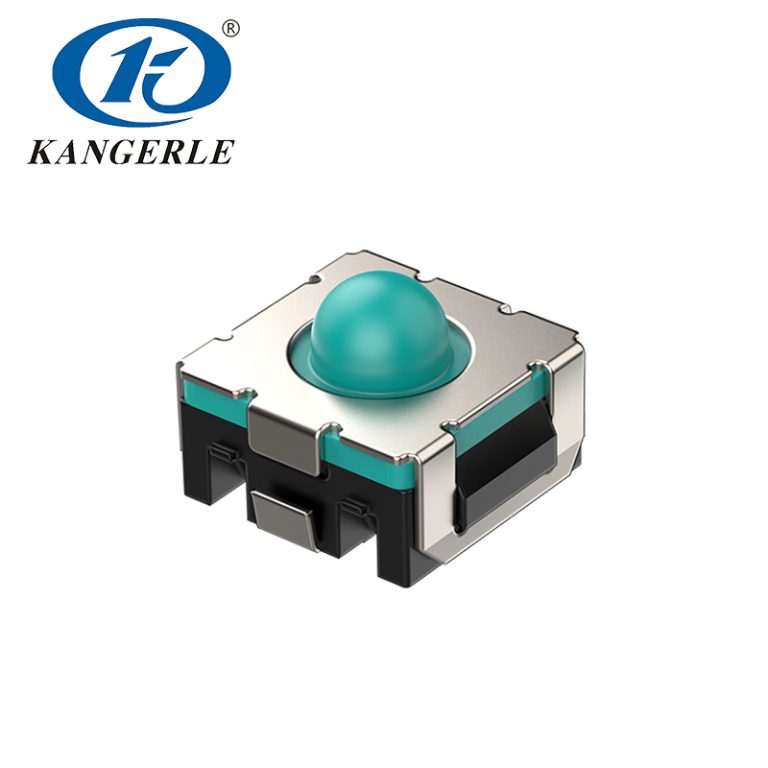

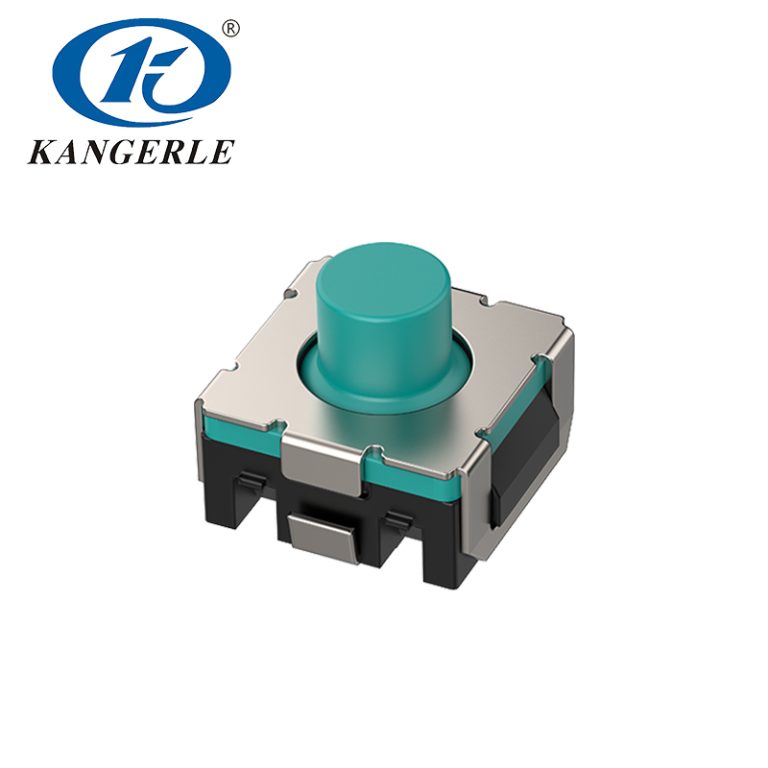

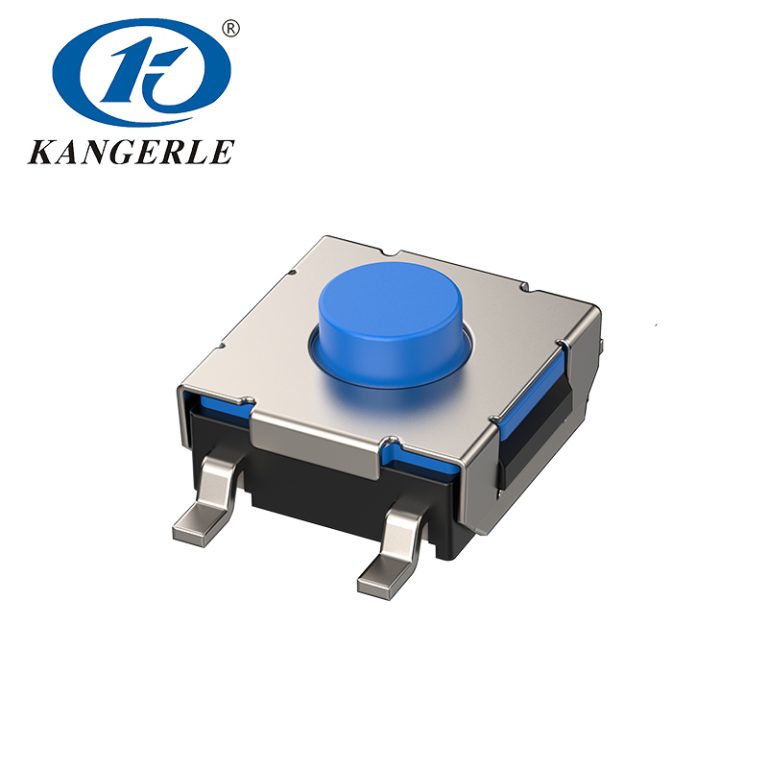

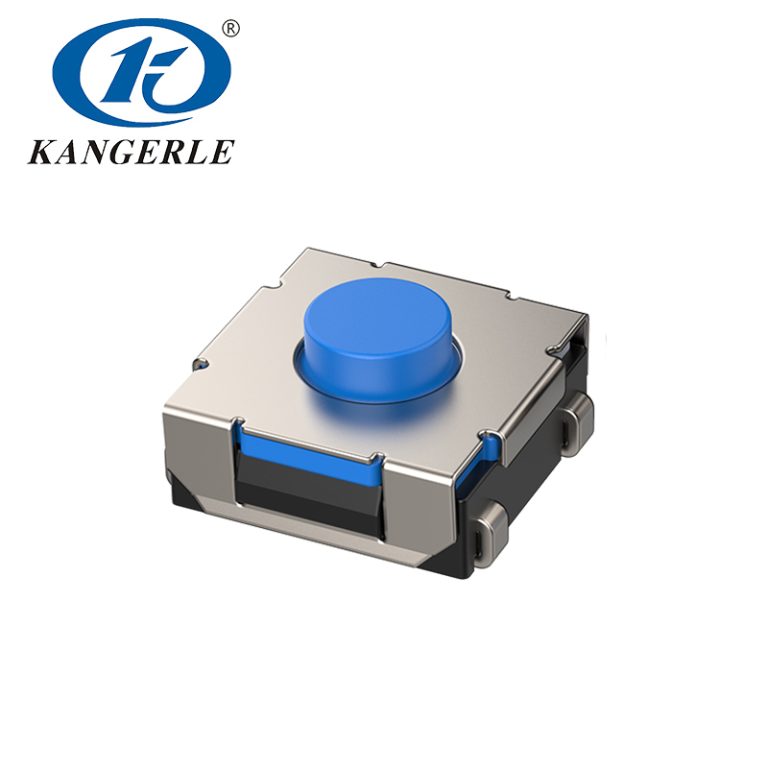

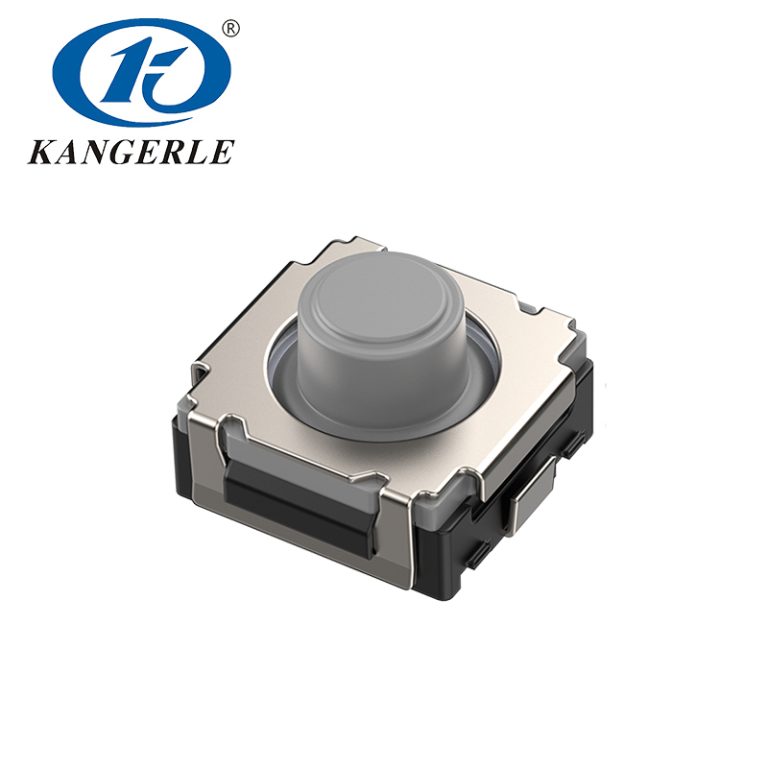

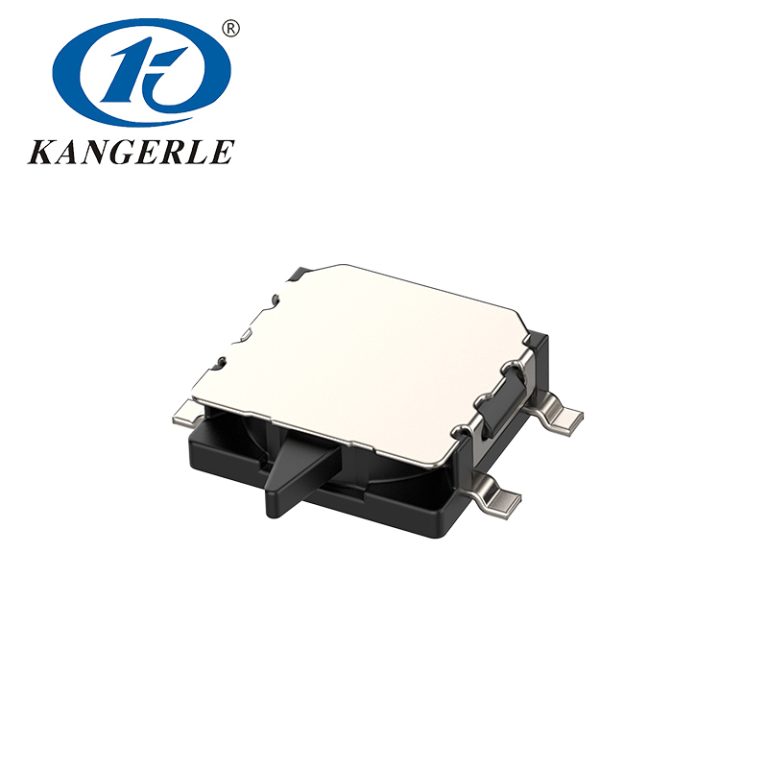

KANGERLE ELECTRONICS, established in the early 1990s in Wenzhou city, has emerged as a prominent manufacturer and supplier of electronic components. With a rich history spanning over two decades, the company has honed its expertise in producing a diverse array of connectors tailored for various industries such as household appliances, security systems, video equipment, communication devices, automotive applications, and computers. For instance, the KANGERLE 2.5mm Pitch 2 Pins Straight Header Connector KEL-XH-2A is designed for reliable and efficient electrical connections, featuring a straightforward pin configuration. The company’s extensive product portfolio is a testament to its commitment to innovation and quality, featuring a wide range of switches designed to meet the specific needs of its clientele.

The company prides itself on a robust team comprising over 20 engineers, 50 technicists, and 40 senior managers, all dedicated to driving the company’s success. Recognized as a STAR ENTERPRISE by the local government, KANGERLE ELECTRONICS has also achieved ISO9001:2015 and IATF:16949 quality management system certifications, underscoring its adherence to the highest manufacturing standards. The switches produced by the company have garnered multiple international certifications, including CB, CE, CQC, TUV, UL, and RoHS, ensuring their global compliance and reliability. With a monthly production capacity exceeding 50 million pieces, KANGERLE ELECTRONICS is well-positioned to meet the demands of its diverse customer base, further solidified by its strategic market presence through agents in Shenzhen, Hanozhou, Ningbo, and Wenzhou.

Future Trends in Connector Technology for Wearables

Integration with Flexible Electronics

As wearable technology continues to evolve, there is a growing trend towards integrating connectors with flexible electronics. This integration allows for more comfortable and ergonomic designs, closely conforming to the body’s natural movements. Flexible connectors are designed to bend and stretch along with the wearable, reducing the risk of damage from constant motion. This trend opens up new possibilities for innovative wearable designs that are both functional and comfortable for the user.

Trends in Wireless Connector Solutions

Another exciting trend in wearable technology is the development of wireless connector solutions. These solutions eliminate the need for physical connectors, reducing wear and tear and enhancing the user experience. Wireless charging and data transfer technologies are becoming increasingly popular, providing users with more convenient and seamless interactions with their devices. As these technologies advance, they promise to further improve the durability and functionality of wearables, paving the way for a new generation of innovative, reliable devices.